- All Products

-

Steel

-

Engineering Steels

-

Stainless Steel

-

304 Grade

- C Section - Channel

- Equal Angle -Mill Finish

- Unequal Angle - Mill Finish

- Sheet - #4 Brush Finished

- Sheet - 2B Mill Finished

- Flat Bar - Mill Finish

- Round Bar - Mill Finish

- Square Bar - Mill Finish

- Pipe (CHS) - Mill Finish

- Square Box Section (SHS) - Mill Finish

- Rectangular Box Section (RHS) - Mill Finish

- Tube - Rectangular

- Tube - Round

- Tube - Square

- Tube Fittings

-

316 Grade

- C Section - Channel

- Equal Angle -Mill Finish

- Unequal Angle - Mill Finish

- Sheet - #4 Brush Finished

- Sheet - 2B Mill Finished

- Flat Bar - Mill Finish

- Round Bar - Mill Finish

- Square Bar - Mill Finish

- Pipe (CHS) - Mill Finish

- Square Box Section (SHS) - Mill Finish

- Rectangular Box Section (RHS) - Mill Finish

- Tube - Rectangular

- Tube - Round

- Tube - Square

- Tube Fittings

- Hex Bar - Mill Finish

- Hollow Bar - Mill Finish

- 431 Grade

-

304 Grade

-

Aluminium

- Brass

- Copper

- Bronze

- Cast Iron

- Mesh and Perforated

- Gauge Plate

-

Silver Steel

Silver Steel

-

Rural Products

- Accessories

- Tools & Gear

Welding series: how to stick weld (for beginners)

What is welding?

Welding is simply the process of using high heat to join two pieces of steel together; the high heat causes the metal to melt, allowing the pieces to fuse together upon cooling.

There are a number of welding techniques to choose from, depending on the environment, application and metals involved in the welding process.

The most basic and common form of welding class is arc welding (where all beginners start), which includes stick welding, metal inert gas (MIG) welding and tungsten inert gas (TIG) welding.

Here, we take you through the stick welding process, a simple but widely used technique, particularly for outdoor settings.

Safety first

Before beginning any welding project, it is vital to ensure all safety measures are in place and you’ve got the right safety gear.

The welding equipment you are using will have specific safety instructions provided by the manufacturer that you must thoroughly review before starting.

You must also have the correct safety equipment on hand to ensure your protection from the heat, sparks and UV rays generated during the process. The essentials include:

- Long-sleeved shirt and pants made from fire-retardant materials

- Gloves

- Safety glasses and helmet

- Adequate ventilation if welding indoors (e.g. exhaust).

The basics

The stick welding process uses an electrical conductor (an electrode) covered with a chemical agent (a flux) to form the weld.

The welding device generates an electric current to form an electric arc between the electrode and the metals you intend to join (the workpiece).

This causes the workpiece to melt and form a weld pool (a pool of molten metal) that fuses together as it cools. During this process, the flux coating on the electrode breaks down and produces a shielding gas and slag, which protects the weld area from corrosion and atmospheric contamination. You will need to chip off this protective layer once the weld has cooled.

Advantages and disadvantages

Advantages

- Stick welding is portable: Edcon Steel stocks the Durally 140 mini stick welder that is just 2kg, making it easily transportable.

- Appropriate for relatively thick metal sections.

- No other equipment is necessary: there is no need for a wire feeder or any other extra equipment, such as a gas cylinder.

- It is one of the most suitable choices for outdoor welding.

- It is suitable for use even if the surface is not perfectly clean (e.g. metal surfaces that have some rust).

Disadvantages

- Skill required: you must keep the electrode at a certain distance from the workpiece while it melts down.

- Mastering stick welding requires a certain level of practice.

- Slag and spatter: stick welding produces a lot of slag and spatter, which can make the process difficult and time-consuming.

- Not as suitable for welding thin material as MIG or TIG.

- The weld produced is not as reliable or of high quality as the TIG weld.

Equipment

Welding device

As a beginner, we recommend a multipurpose welding machine that allows you to practise a number of welding techniques, such as stick, TIG and MIG.

Ground clamp

It is important to use a ground clamp with the welding device. Plug the ground clamp into the welding device and clamp it onto the section of metal you are going to weld.

Electrodes

Electrodes are dependent on the project. But in order to know which electrode is appropriate, you will need to understand the numerical categorisation.

Electrodes are categorised using four digits, with the first two digits indicating the lowest tensile strength of the base material. For example, if the number starts with 60, that means the tensile strength is 60,000 psi.

The third digit refers to the position where you can use the electrode. Number one means you can use it in any position; number two means you should only use it in a flat position.

The final digit indicates the suitable electrical current, as well as the electrode coating. Following the digits are the type of coating.

Practice makes perfect

When setting up your welding device, you should always follow the manufacturer’s instructions and ensure all settings are correct.

If you’re a beginner, you should always practise with scrap metal before moving on to welding projects.

Edcon Steel keeps a range of metal and steel offcuts at all our stores that are perfect for practice.

While striking the electrode to create an arc is the trickiest part of the process, once you nail this, the rest of the process is quite simple!

Then just keep practising!

Are you looking for complete steel solutions?

Edcon Steel is Australia’s most comprehensive online steel and metal superstore. We cut and supply steel and metal – in a wide range of shapes, sizes and grades – for all your project needs.

We know metal and steel – and we know our customers appreciate our service and stockholding, so feel free to contact us for your steel or metal solution today.

Read more steel articles

Our most popular steel and metal products

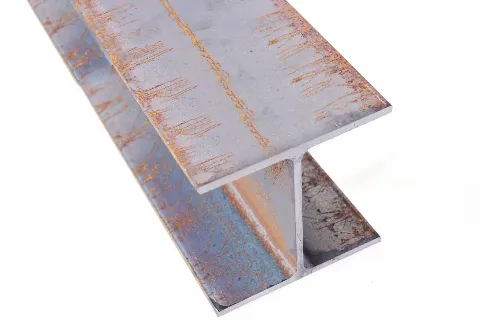

Structural Steel Beams, C-Section, Columns, Angles

Browse Now

316 Stainless Steel. Sheet & Plate, Angle, Bar, Pipe, Tube

Browse Now

Precision Metals - Gauge Plate & Silver Steel

Browse Now

Cattle & Sheep Handling. Steel Panels, Gates, Ramps, Crush

Browse Now

Buy Rural Fencing Online. Wire, Pickets, Posts, Gates

Browse Now

Buy Welded Mesh Online. Mesh and Perforated

Browse Now

Tubular Steel. Rectangular (RHS), Square (SHS), Pipe

Browse Now