Stainless Steel 304 Grade

Custom-cut to order Delivery or Click & Collect

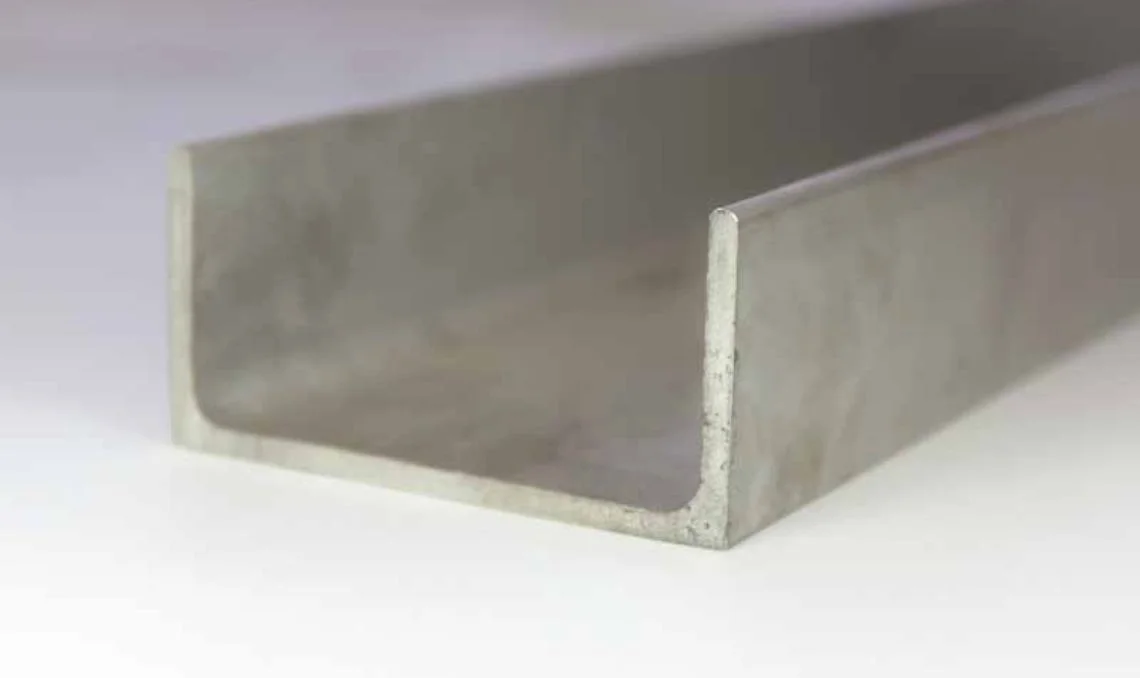

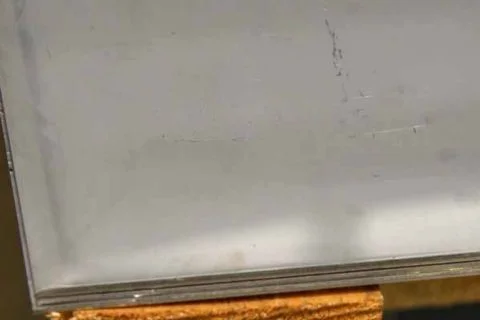

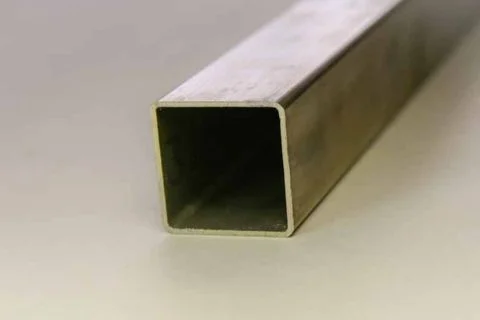

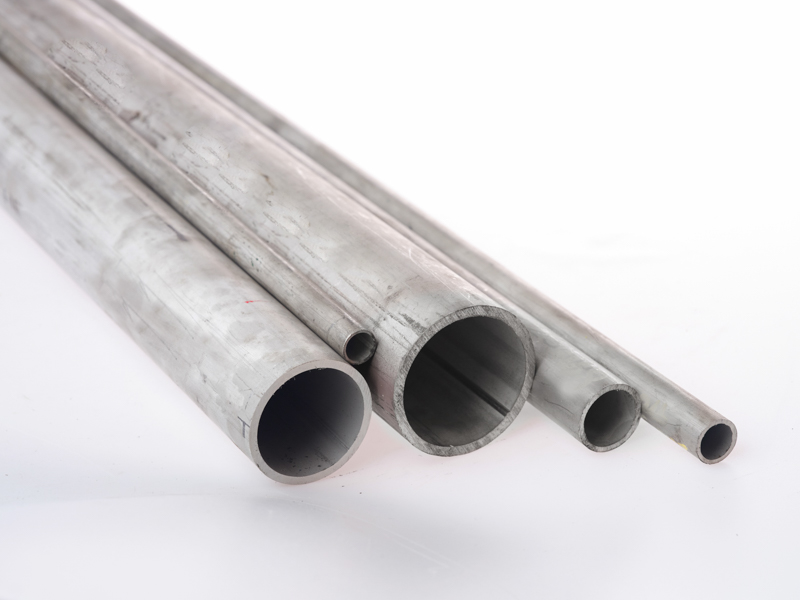

Angel equal; angle unequal; c-section channel; flat bar; pipe bar; SHS; RHS; CHS; round bar; sheet and plate; square bar

304 Grade Stainless Steel is an entry level austenitic stainless steel with superior corrosion protection than uncoated Mild Steel. 304 Grade Stainless steel represents around 50% of the stainless steel consumed in Australia, but with limitations in warm and high chloride environments it is not recommended for marine or warm high chloride processing applications. 304 Grade Stainless Steel has many common names customers may know it by “Furniture Grade Stainless “or “Kitchen Grade Stainless” and sometimes called “10/18 Grade Stainless” or “10/18”.

Search below for Stainless Steel 304 Grade only.

|

Show

entries

|

||||||||

| Image | Stock Code | Description | Grade | Shape | Dimensions | Standard Size | Metal | |

|---|---|---|---|---|---|---|---|---|

|

|

View Price | |||||||

|

Loading...

|

||||||||

|

No Results found.

|

||||||||

Characteristics

304 Grade Stainless Steel should have low magneticity and has a high tensile strength . Welding of 304 Stainless Steel is possible, but care will be needed to clean welds and areas effected by heat decolourisation from the welding processes.

Density 7,900 lg/m3

Tensile Strength 515 MPa

Brinell Hardness 201 HB

Rockwell Hardness 92 HRB

Common Applications

304 Stainless steel will be considered in :

- Cutlery

- Sinks

- Furniture

- Handrails

- Architectural Applications

Edcon Steel Tips

- Edcon Steel has 50 years of metal expertise – we’re Australia’s most comprehensive online steel and metal superstore – so if you need stainless steel in just about any available size, shape, grade or dimension, we can help you.

- For decades we’ve serviced major infrastructure projects – and home handymen. We are here for tradespeople, home builders, renovators… and plenty of others with a passion for metal projects.

- Our 304 stainless steel options include angles, bars, boxes, tubes, pipes, plates, welding consumables and a range of accessories. We have access to these products via a network of Australia’s best known names in Stainless Steel, but in most cases we do not stock 304 Stainless Steel. We will only supply 304 Stainless Steel in economical lengths.

- For cut to size stainless steel items, we do stock 316 Stainless Steel which can cut to your requirements.

- Ready to get started buying stainless steel online? Simply use the selector below for a quote or contact us for advice on the right stainless steel for your project.

Surface Preparation and Coatings

Unlike mild steel the chemistry of stainless steels means the processes and methods for protecting and finishing 304 Grade Stainless Steel are vastly different to mild steels. Most surface finishes for stainless steel will be mechanically (Polishing) or chemically (Passivating) applied. The correct surface finish will have substantial impacts on the performance and appearance of your stainless steel.

One of the most important considerations for the performance and appearance Stainless Steels is cleanliness. Surfaces need to be kept free from particles of other metals especially alloy or carbon steels. Timber also has contaminants that will leech and stain stainless steels.

Due to the variety of finishes available in stainless steels, Edcon Steel strongly recommends you discuss your requirements with your designer or fabricator.

Our most popular steel and metal products

Need some inspiration? Check out our customer projects

St Dominic’s Yarning Circle

The innovative design concept of the Yarning Circle helped to transform an unused outdoor space into a central meeting hub for the school community at St Dominic’s College in Sydney.

Learn More

3801 steam train

From the workshop benches to the materials used on the train, Edcon was there to provide the quality steel and metal needed to restore the 3801 steam train.

Learn More

Don Wimer, American Ramp Company

The Wollongong landscape is transforming – and it’s a dream come true for skaters and scooters across the city.

Learn MoreLeading brands

Edcon toolbox

What is the difference between pre-gal and hot-dip galvanised steel?

Learn More

304 vs 316 stainless steel

Learn More