Buy Structural Steel C-Section - Channel Online

Custom-cut to Order Delivery or Click & Collect

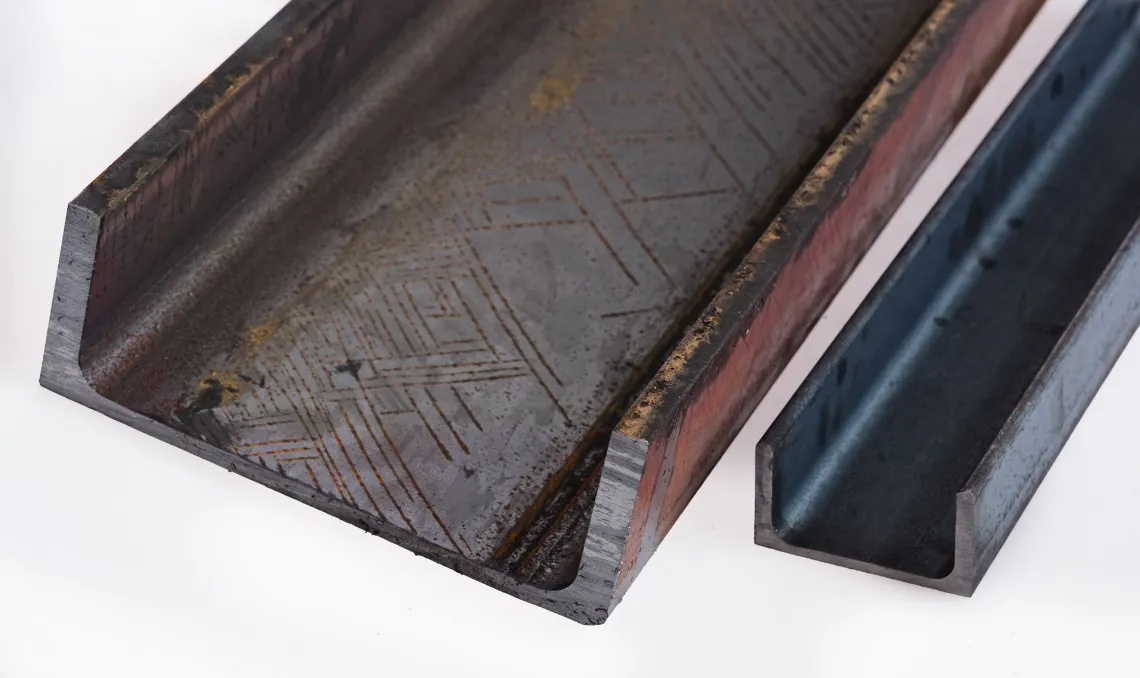

Structural steel channels, also known as C-section, C-channels or Parallel Flange Channels (PFC), are structural steel beams shaped like the letter “C.” They consist of a vertical web and two horizontal flanges, forming a flat back surface with an open channel on the other side. This design gives C-section channels a high strength-to-weight ratio, meaning they provide exceptional strength and load-bearing capacity without excessive weight. The flat back also makes channels easy to bolt or mount to other flat surfaces, offering great versatility for construction and framing purposes.

At Edcon Steel, we stock a comprehensive range of structural steel channels to suit projects of any size. Our channels are made from high-quality hot-rolled mild steel (Grade 300+) and are Australian-made wherever possible, meeting all relevant Australian standards for structural integrity.

We also offer post-fabrication galvanising for all PFC and channel products to suit outdoor or corrosion-sensitive applications. Learn more about that process here.

Order online for nationwide delivery, or visit one of our NSW stores in Brookvale, Revesby, Blacktown, Bathurst, and Orange for expert advice and local pick-up.

Explore the product groups below to find the right structural steel solution for your next project.

Search below for Steel C Sections only.

|

Show

entries

|

||||||||

| Image | Stock Code | Description | Usage | Dimensions | Standard Size | |||

|---|---|---|---|---|---|---|---|---|

|

|

View Price | |||||||

|

Loading...

|

||||||||

|

No Results found.

|

||||||||

Key Specs & Options: Structural Steel C-Section Channels

Note: Edcon Steel also supplies structural C-channel profiles in other materials for special applications. These alternatives are separate from the standard hot-rolled 300PLUS mild steel PFC products detailed above.

Cut to Size. Packed. Delivered.

- We can custom cut lengths to the millimetre – minimum cut just 15 mm.

- Cut-to-size items are available in-store while you wait, and online orders are processed the same day or the next day in most cases.

- Shorter cuts are cheaper to ship and sent via couriers or Australia Post.

- Large or long orders are delivered by our own delivery truck fleet in NSW or by national freight partners.

Work Smarter with Edcon Steel

Plan Your Lengths: Structural channels are typically stocked in 9 m and 12 m lengths. Plan your project around these standard lengths to minimise off-cuts and save on cost. Our team can also precision-cut channels to your specifications, so you only buy (and pay for) the lengths you need.

Choose the Right Finish: Mill (raw) or primed channels work well for indoor or sheltered uses. We also offer post-fabrication galvanising for all PFC and channel products to suit outdoor or corrosion-sensitive applications. Learn more about that process here.

Cut & Handle Safely: Always wear proper PPE (gloves, eye protection, etc.) when cutting or handling steel. After cutting a channel, de-burr any sharp edges to prevent injuries and to ensure a clean fit during assembly. Don’t have the right tools? We can custom-cut your channel to exact lengths for you, in-store or as part of any online order.

Join Smartly: For bolted connections, use appropriate hardware like steel plates, cleats, or brackets (Edcon stocks a wide range) to create strong joints between channels. If you’re welding galvanised channel sections, make sure to grind off the zinc coating in the weld area and then re-coat it after welding to maintain corrosion protection on the finished work.

Check with a Professional: The information here is general in nature. Always confirm your specific channel sizes, load requirements, and design plans with a qualified engineer or builder before installation. This ensures your project is compliant with building codes and safety standards.

Common Uses and Sectors: Structural Steel C-Section Channel

Structural steel channels are widely used across residential, commercial, industrial, and infrastructure projects thanks to their strength and versatility. In building construction, C-section channels often serve as critical support and framing members. They are commonly used as lintels above doors and windows, as floor joists and roof purlins/rafters, and as bearers or bracing members in frameworks. The flat backside of a channel makes it easy to bolt against walls, concrete, or timber, so channels are ideal for forming columns, beams, and frames where a flush-mount structural element is needed.

Thanks to their high strength-to-weight ratio, structural steel channels can support heavy loads (such as roof trusses or mezzanine floors) without adding unnecessary bulk. This makes them a popular choice for outdoor and secondary structures including carports, pergolas, garages, and sheds.

Beyond building and housing, structural channels also play a key role in infrastructure and industrial settings. They are used in bridge trusses, platform supports, and equipment frames, as well as in the manufacturing, mining, and agricultural sectors. From home DIY projects to large-scale commercial builds, structural steel C-section channels deliver reliable, easy-to-install strength across all these industries and applications.

For more information, read our blog about Builders Steel. Additionally, the OneSteel guide for builders and owner-builders provides support in the design, sizing, and applications of structural steel for domestic and house building.

Steel in Action: Projects & Know-How

Frequently Asked Questions

What is a structural steel channel (C-section / PFC)?

What material grade and standard do your steel channels comply with?

Edcon Steel stocks hot-rolled mild steel channels made to the 300PLUS grade (with a minimum yield of about 300 MPa), and conforming to the Australian standard AS/NZS 3679.1.

What size ranges and weights are available?

Typical depth × flange sizes start around 50 × 25 mm (smallest) and go up to 380 × 100 mm (largest) for the standard channel stock. Approximate mass ranges from ~7.1 kg/m at the small end up to ~55.2 kg/m for the largest.

Can I get custom-cut lengths or fabrication services?

Yes — channels can be custom cut to the millimetre (minimum cut of around 15 mm) and can be drilled or modified as required. Shorter cuts make shipping cheaper; large or longer orders go by truck/freight.

What finishes or coating options are available?

By default the channels are supplied in mill finish (raw/uncoated). Optional protective coatings (e.g., primed/painted or post-fabrication hot-dip galvanising) are available for outdoor or corrosion-sensitive applications.

How do I choose the right channel for my project?

Important factors include the span and load it must support, the environment (indoor/outdoor/coastal), whether the channel will be exposed or painted, whether fabrication (holes, plates, welding) is required, and the finishing/coating needed. Consulting a structural engineer is advisable if uncertain.

What stock lengths are typically available, and how can I plan to minimise waste?

Standard stock lengths are generally around 9 m or 12 m (varying by section). Planning your project around these full lengths (or requesting cuts) will minimise off-cuts and reduce cost.