Structural welding processes and techniques

Welding of steels and metals is one of the features that make it such a great, useful product for so many people.

Structural welding is a crucial part of the steel fabrication process… a fabricated steel structure is only as strong as the welds that join it together.

At Edcon Steel, our focus on quality starts well before our welders start their job. Edcon Steel understands compliance and efficiency in our structural welding.

This comes from understanding what makes a compliant weld and ensuring we have all the right parts in place before any welding takes place, to ensure consistent, quality welding.

We have been fabricating steel for more than 50 years, and in that time we have identified five important factors that will affect the final weld quality.

Welding needs to be planned well before any arc is struck. Here at Edcon Steel we will plan our welding process and consider five important factors prior to our welders starting the job :

- Process – selecting the correct structural welding process.

- Preparation – joint configuration must be right and compatible with the process.

- Procedures – following procedures for uniform and repeatable results.

- Pretesting – of joints that have had no previous procedure prepared or are not prequalified to a standard.

- Personnel – assigning qualified people to each task.

Australian welding standards

To comply with Building Standards in Australia, all welding must comply with the relevant Australian standards. In the case of structural steel welding, that standard is AS/NZS1554.1 – Welding of Structures.

Under these standards, all structural welding work must be carried out by qualified welders who comply with the appropriate requirements of the standards; Procedure Qualification Records (PQR) must be available to all welders during fabrication by way of Welding Procedure Sheets (WPS); and a welding supervisor must oversee all welding work.

At Edcon Steel, we are also members of Weld Australia – the peak body for welding in Australia – along with other steel industry associations.

We are currently in the process of obtaining AS/NZS ISO3834 certification and accreditation to provide clients with assurance in the weld quality Edcon Steel provides.

Structural welding processes

For structural steel fabrication, there are two main welding processes we use. These are:

- Gas Metal Arc Welding (GMAW) or Metal Inert Gas – commonly known as MIG – which uses a shielding gas such as argon or helium to shield the welding arc and prevent oxygen and hydrogen contaminating the weld. This is by far and away the most common welding process in Australia. It is a versatile and speedy process that can be semi-automated or automated. MIG welding produces a better weld appearance and has higher deposition rates and is therefore the preferred welding process.

- Manual Metal Arc Welding (MMAW) or ‘Stick Welding’ whereby an arc is struck between an electrode and the metal being welded. Stick Welding is a simple and efficient process. Unlike GMAW, the shielding used in MMAW is a flux coating, produced as the electrode melts. This flux needs to be removed and adds to the labour on the welding process. As a welding process, it produces sound and reliable welds, and has advantages in outdoor or drafty situations where wind can blow shielding gases away from the welding arc.

Types of structural welds

When it comes to structural steel welding, you generally need a continuous weld – such as a butt or fillet weld – to give your structure the strength and stability it needs.

So when do you use a butt weld and when do you use a fillet weld?

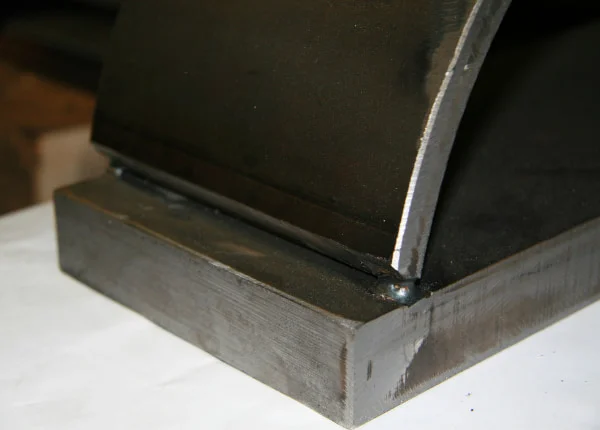

A fillet weld is used where the two surfaces being welded lie perpendicular to each other.

A butt weld on the other hand acts more like a seam where the two surfaces being welded are in the same plane.

However, continuous welds do have their downsides… distortion and cost. In some cases, stitch welding is an acceptable alternative.

It is important to consider the engineering performance, safety factors and desired appearance of welds before commencing a job to ensure your welder is fully briefed on your requirements.

Butt welds

Butt welds are formed when the welder feeds molten metal between two pieces of almost-touching metal. The size of the gap is critical to the success of the weld – too small and you won’t achieve penetration… too big and you will end up with a heavy seam.

AS/NZS1554.1 allows for two types of butt weld – complete penetration and partial penetration.

Partial penetration butt welds are used in low stress areas on structures. Complete penetration butt welds, on the other hand, are used for high stress joints where the full strength of the joined components is required.

Most butt welds require special edge preparation, which is a factor that can impact the cost. Some welds can take longer in weld preparation than the weld itself!

The technique for fillet welds is much faster than butt welds – partly because it doesn’t require any edge preparation. It is for this reason that fillet welds are some of the most widely used joints.

However, they also require a higher level of skill to ensure accuracy and consistency. As with all welds, the position of the weld is important. With our purpose built workshop we can position most welds to allow for downhand welding.

This downhand position is the easiest, fastest and most consistent position to weld in.

Compared to butt welds, fillet welds in several configurations do not have the load carrying capacities and fatigue characteristics of the more time consuming butt welds.

The trick with a fillet weld is to ensure that the throat of the weld is the same as the thickness of the base metal. A strong fillet weld is when the finished weld surface sits at a 45° angle to both pieces of base material.

Stitch welding

Stitch welding produces an intermittent – as opposed to continuous – weld.

It gets its name from the stitch like appearance of the weld once it is completed, with small consistently spaced gaps between the welds.

Stitch welds are lower cost and can also prevent heat distortion… combatting two of the downsides of continuous welds.

However, because of the gaps between the welds, stitch welding is not as robust or durable as a continuous weld so should only be used in cases where durability is not a deciding factor or the need to prevent heat distortion outweighs the requirement for durability.

Our Welding Process

1. Review the Drawings

We check your steel spec and connection details before welding begins.

2. Weld to Specification

Our qualified in-house welders fabricate to Australian Standards (AS/NZS 5131), using MIG, TIG or stick depending on the job.

3. Visual Inspection

Welds are visually checked, cleaned, and marked. We can also complete onsite welds or adjustments if needed.

Expert structural welding and steel fabrication

At Edcon Steel, we have a purpose built steel fabrication facility located in Brookvale, 16km north of the Sydney CBD. We have the expertise and capability to complete structural steel projects – both big and small.

We’re also Australia’s most comprehensive online steel and metal superstore, so if you’re looking for products for your next project, we’ve got you covered. We cut and supply steel and metal – in a wide range of shapes, sizes and grades – for all your project needs.

Read more steel articles to find out more about the steel industry, customer projects and product resources.

End-to-End Project Examples

From small residential builds to complex, multi-stage installations — here’s how we deliver structural steel that performs in the real world.

Shore Grandstand 2

Full-service package including detailing, fabrication, and hased delivery.

Yarning Circle Project

Curved steel elements fabricated in-house and installed

on-site.

Mosman Residential Steelworks

Custom-fabricated steel for a complex residential project.

Tools, Services & Support

Explore coatings, welding services, and project insights that support every stage of your build.

Structural SteelStructural Steel Articles

Frequently Asked Questions

Does Edcon weld structural steel in-house?

Yes. All welding is completed by qualified in-house staff and checked before coating or dispatch.

Do your welds meet Australian Standards?

Yes. We follow AS/NZS 5131 for all structural welds and can meet specific project or compliance requirements.

Can Edcon weld from supplied drawings or specs?

Absolutely. We work directly from your structural drawings and connection details.

What type of welding does Edcon offer?

MIG, TIG, and stick welding depending on the job and steel type. Onsite weld adjustments can also be arranged.