Buy Structural Steel Angles Online

Custom-cut to Order Delivery or Click & Collect

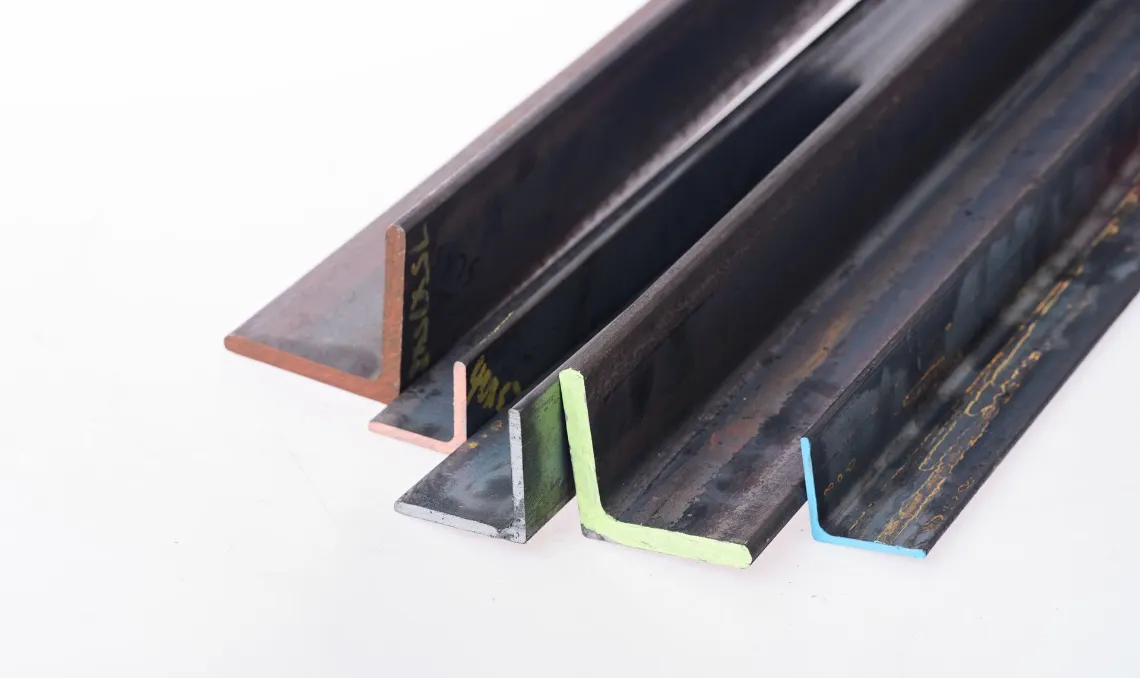

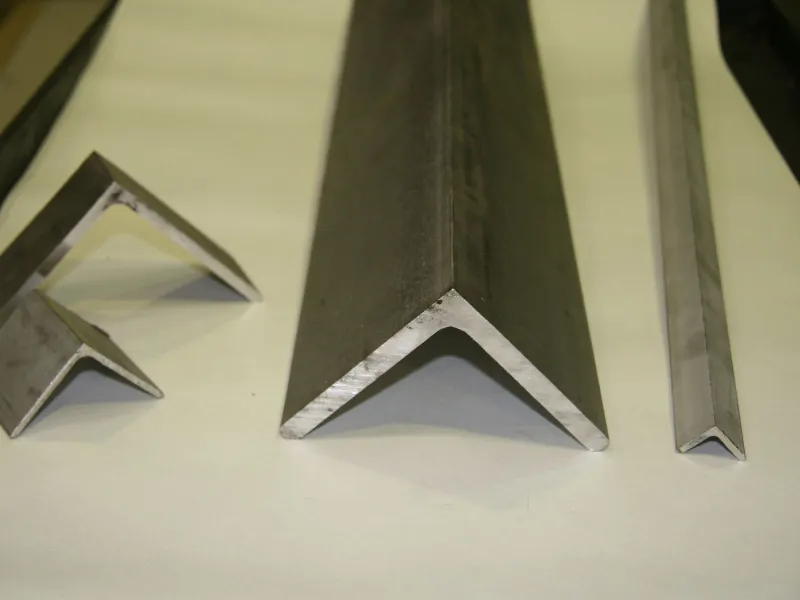

Structural steel angles (often referred to as angle iron, L-angle or L-bracket) are L-shaped steel sections that are essential in construction and fabrication projects.

Equal angles have both legs of the “L” the same length, whereas unequal angles have differing leg lengths to suit specific design needs. Despite this difference, both types feature a 90° angle and provide excellent versatility, strength, and structural support at a competitive price point. These qualities make structural steel angles fundamental components for frames, bracing, shelves, lintels and more in all kinds of builds.

At Edcon Steel, we offer a comprehensive range of both equal and unequal angle profiles, reflecting our status as Australia’s most comprehensive online steel and metal store.

Order online for nationwide delivery, or visit one of our stores in NSW (Brookvale, Revesby, Blacktown, Bathurst, and Orange) for expert advice and local pick-up.

Explore the product groups below to find the right steel solution for your next project.

Search all Structural Steel Angles below.

|

Show

entries

|

||||||||

| Image | Stock Code | Description | Standard Size | |||||

|---|---|---|---|---|---|---|---|---|

|

|

View Price | |||||||

|

Loading...

|

||||||||

|

No Results found.

|

||||||||

Key Specs & Options: Structural Steel Angles

| Specification |

Details |

| Equal Angles – Size Range | Leg lengths from 25 x 25 mm up to 200 x 200 mm (approx. 1″ x 1″ up to 8″ x 8″). Thicknesses range from 3 mm on smaller angles to 26 mm on the largest standard sections. These cover small angle irons for light fabrication through to heavy structural angles. |

| Unequal Angles – Size Range | Leg lengths from 75 x 50 mm up to 150 x 100 mm (approx. 3″ x 2″ up to 6″ x 4″). Thicknesses generally range from 5 mm to 12 mm for these sections\. Unequal angles provide flexibility where one leg needs to be longer for support or attachment. |

|

Materials Available |

– Mild Steel – Hot-rolled 300PLUS structural steel (min 300 MPa yield) for maximum strength. – Pre-Galvanised Steel – e.g. Duragal® angles (C450 grade) with a light zinc-aluminium coating for internal/external use. – Hot-Dip Galvanised – Mild structural steel angles coated to AS/NZS 4680 standard for full zinc protection (ideal for outdoors). – Stainless Steel – 316 Grade marine grade stainless angles for superior corrosion resistance in harsh environments. – Aluminium – 6060-T5 alloy angles for a lightweight, non-rusting option (suitable for light frames, not structural load-bearing). |

| Finishes / Coatings | Mill finish (raw, uncoated steel with mill scale) is standard for most hot-rolled angles. Customers can optionally get angles primed/painted (anti-rust primer or other paint) or Hot-Dip Galvanised (HDG) for corrosion protection. Galvanising adds a zinc coat ~85 µm thick, bonding to the steel – perfect for exterior use. Stainless angles come in a mill finish (dull gray) unless polished. |

|

Stock Lengths |

Common stock lengths are 6.0 m for smaller merchant-bar angles and 9.0 m or 12.0 m for larger structural angles. Some sections may also be available in ~8 m or ~6.1 m (20 ft) lengths. Edcon Steel offers custom cutting on all angles – we will supply any length you require, so you don’t have to buy more than you need. Standard long lengths can be delivered or collected from our branches. |

|

Mass (Weight) per Length |

Unit weight depends on size and thickness. For example, a 25 x 25 x 3 mm mild steel angle is about 1.12 kg per metre, whereas a hefty 200 x 200 x 26 mm angle is ~76.8 kg per metre. Most structural angles fall in between these extremes. Refer to our weight tables or online calculator for exact masses per length of each profile. (Density of steel ≈ 7850 kg/m³; aluminium ≈ 2700 kg/m³ for comparison.) |

|

Standards |

Edcon’s structural steel angles conform to AS/NZS 3679.1 (Grade 300) for hot-rolled structural steel. This ensures consistent mechanical properties and quality. Hot-dip galvanising meets AS/NZS 4680 for zinc coatings. Stainless structural steel angles meet ASTM standards (e.g. ASTM A276 for 316 profiles). Certifications can be provided upon request. |

(Note: Imperial sizes are approximate. 1 inch = 25.4 mm. Thickness 1 mm ≈ 0.04 inch.)

Cut to Size. Packed. Delivered.

- We can custom cut lengths to the millimetre – minimum cut just 15 mm.

- Cut-to-size items are available in-store while you wait, and online orders are processed the same day or the next day in most cases.

- Shorter cuts are cheaper to ship and sent via couriers or Australia Post.

- Large or long orders are delivered by our own delivery truck fleet in NSW or by national freight partners.

Work Smarter with Edcon Steel

Plan Your Lengths: Planning your project around these sizes minimises offcuts and saves on cost. Our team can custom-cut to your specs for maximum value.

Match the material to the job: If your project is outdoors or damp, consider galvanised steel or stainless structural steel angles so you won’t have to worry about rust. In coastal/marine environments or for food-grade projects, 316 stainless angles are worth the investment for their superior corrosion resistance. Always ensure you’re using structural-grade steel (300 MPa) for load-bearing applications, and if weight is a concern (or the angle isn’t structural), lightweight aluminium angles might be an option.

Store steel properly to prevent damage: Keep structural steel angles dry and off the ground during storage. If they’re delivered to site before use, place them on timber skids or racks to prevent moisture accumulation and ground contact, which can lead to rust.

Common Uses and Sectors: structural steel angles

structural steel angles are a go-to solution across many industries thanks to their strength, versatility, and ease of use. In construction, they serve as lintels, purlins, framing components, and wall supports in both residential and commercial projects. Infrastructure and mining sectors use equal and unequal angles for cross-bracing, gantries, towers, and support frames where durability is critical.

In manufacturing and fabrication, angles form machinery bases, shelving, benches, and racking systems. Their simple profile makes them easy to cut, weld, and bolt. Transport and automotive projects rely on angles for trailer chassis, vehicle frames, and 4×4 builds, while marine and coastal applications benefit from corrosion-resistant stainless steel options.

DIYers and farmers use mild structural steel angles for gates, brackets, garden beds, and shed frames due to their affordability and workability.