Buy Bright Mild Steel (BMS) Online

Custom-cut to Order Delivery or Click & Collect

At Edcon Steel, we stock 1020-grade Bright Mild Steel(BMS) in various profiles, including flat bars, round bars, square bars and hex bars, all featuring a smooth, plain surface. BMS bars come in standard 6 metre lengths and can be cut to any size you need while you wait in-store or as part of your order.

BMS is a low-carbon steel known for its smooth, bright surface finish and reliable strength. Through a special cold-finished process, BMS achieves tighter tolerances and a cleaner surface than standard hot-rolled mild steel, making it easier to machine and weld.

BMS is often chosen for its improved machinability and neat appearance in projects ranging from precision-engineered machine parts and shafts to decorative metalwork and custom brackets. It’s still just as weldable and versatile as ordinary mild steel, but with a better finish right off the shelf.

Order online for nationwide delivery, or visit one of our stores in NSW (Brookvale, Revesby, Blacktown, Bathurst, and Orange) for expert advice and local pick-up.

Explore the product groups below to find the right engineering steel solution for your next project.

Search below for Engineering Steel Bright Mild(BMS) only.

|

Show

entries

|

||||||||

| Image | Stock Code | Description | Usage | Dimensions | Standard Size | |||

|---|---|---|---|---|---|---|---|---|

|

|

View Price | |||||||

|

Loading...

|

||||||||

|

No Results found.

|

||||||||

Key Specs & Options: Bright Mild Steel (BMS)

|

Shape |

Dimensions (range) |

Material |

Finish |

Standard Stock Length |

| Flat Bar | Width: 10 mm – 100 mm; Thickness: 3 mm – 25 mm | 1020 Bright Mild Steel | Smooth plain finish | 6 m |

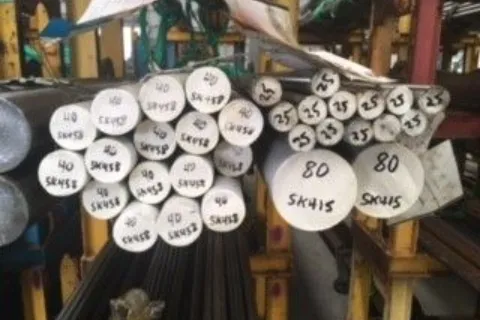

| Round Bar | Diameter: 3 mm – 75 mm | 1020 Bright Mild Steel | Smooth plain finish | 6 m |

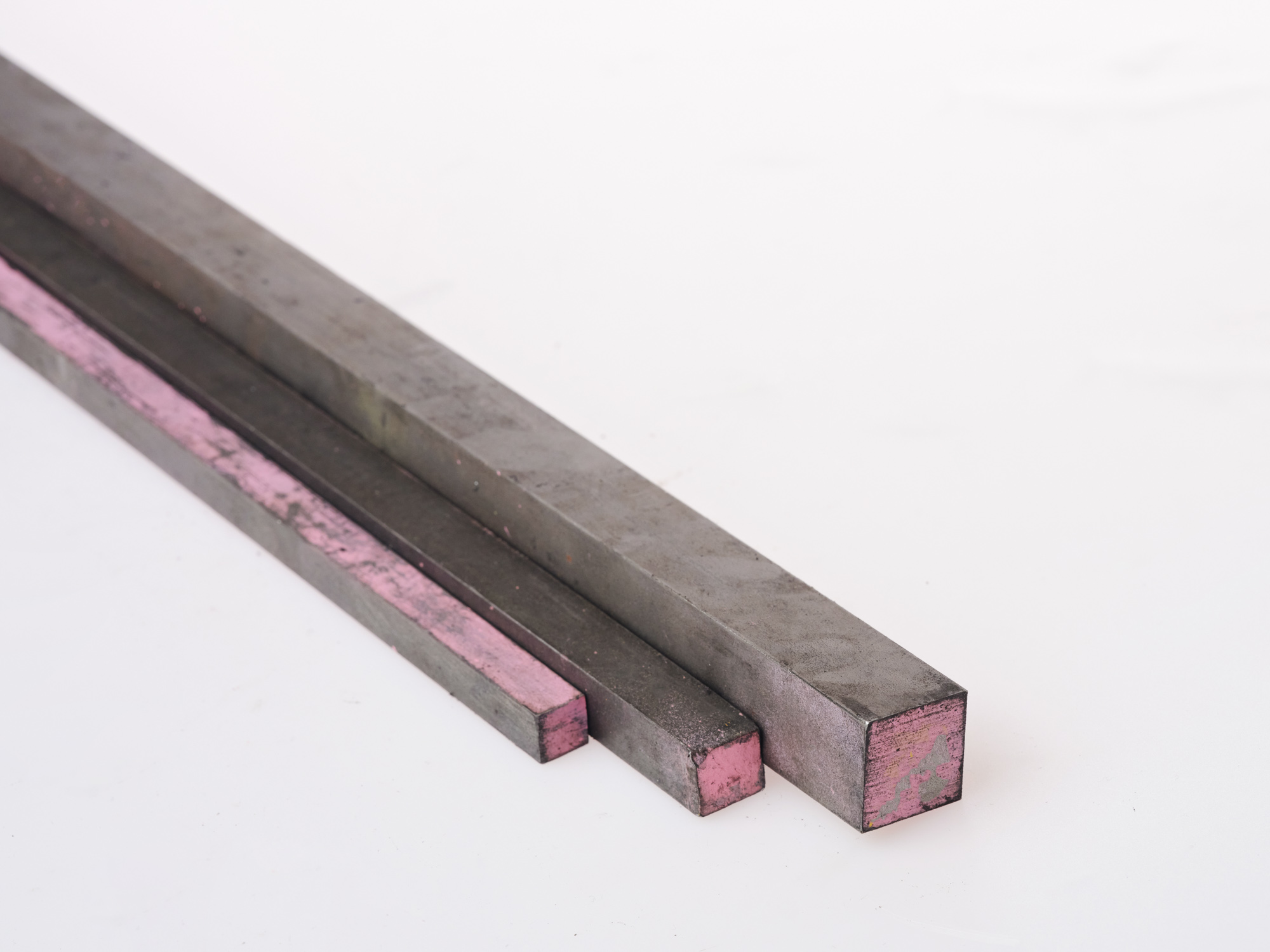

| Square Bar | Side: 6 mm – 65 mm | 1020 Bright Mild Steel | Smooth plain finish | 6 m |

| Hex Bar | Across Flats: 10 mm – 38 mm | 1020 Bright Mild Steel | Smooth plain finish | 6 m |

Cut to Size. Packed. Delivered.

- We can custom cut lengths to the millimetre – minimum cut just 15 mm.

- Cut-to-size items are often available in-store while you wait, and online orders are processed the same day or the next day in most cases.

- Shorter cuts are cheaper to ship and sent via couriers or Australia Post.

- Large or long orders are delivered by our own delivery truck fleet in NSW or by national freight partners.

Work Smarter with Edcon Steel

Plan Your Lengths: BMS bars come in standard 6 m lengths. Designing with this in mind reduces offcuts and saves money. Our team can help you plan cuts for maximum value.

Choose the Right Gauge: BMS is easy to cut, drill and machine with common tools. Use sharp bits/blades and a bit of cutting fluid or oil when drilling or machining to get a clean, accurate result without overheating the meta

Store it Right: Keep your bright steel dry and indoors if possible as BMS can develop light surface rust if left in the rain or humidity. A light coat of machine oil or primer on the surface will protect the steel during storage, preserving that smooth finish until you’re ready to use it.

Cut & Handle Safely: BMS may have a smoother surface, but freshly cut edges can still be sharp. Always wear gloves when handling steel, and get a friend or use equipment to assist with lifting long or thick pieces to stay safe.

Check with a Professional: All information here is general. Always confirm your steel sizes and load requirements with a qualified engineer or builder before installation to ensure compliance and safety.

Common Uses and Sectors: Bright Mild Steel

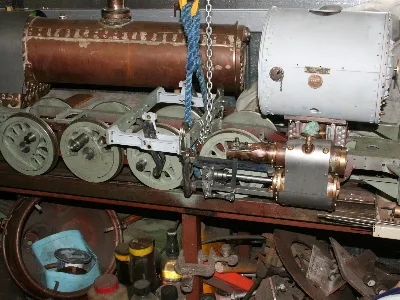

Bright mild steel (BMS) finds use across a broad range of applications in building, fabrication, and engineering. Its smooth finish and accurate dimensions make it ideal for precision components and fittings, like axles, shafts, hinges, pins, threaded rods and machine parts..

In the construction world, BMS flat bars and rounds often become base plates, bracing, cleats or custom brackets in residential and commercial projects where a clean look or exact fit is important.

Because it’s a mild steel, it can be cut, drilled, welded, bent and machined to suit all kinds of jobs without fuss. From making DIY metal furniture or hardware to repairing equipment and assembling structural components, BMS offers a great combination of strength and workability for professionals and hobbyists alike.

We supply BMS to Sydney tradies and builders daily, and to fabrication workshops in regional areas. Our NSW stores in Brookvale, Blacktown, Revesby, Bathurst, and Orange keep a range of bright steel in stock for local pickup. Not nearby? No worries – we deliver bright mild steel nationwide, from city suburbs to rural towns.

For more information, read our Steel and Metal articles.

Steel in Action: Projects & Know-How

Frequently Asked Questions

Can I get BMS cut to size at your stores?

Yes. All Edcon stores (Brookvale, Revesby, Blacktown, Bathurst, and Orange) and our online store, offer cut-to-size services for BMS. We cut while you wait, or prepare your order for pickup or delivery.

Do you deliver BMS outside of Sydney and regional NSW?

Yes. We deliver across Sydney daily and throughout the Central West from our Bathurst and Orange stores. Outside NSW, we ship nationwide with trusted freight partners.

Can I pick up my order in-store?

Yes. Use our free Click & Collect service from Brookvale, Revesby, Blacktown, Bathurst, and Orange. We’ll prepare your order and notify you when it’s ready for pickup.

Where can I buy BMS in Sydney?

Visit Edcon Steel in Brookvale, Revesby, or Blacktown, or shop online 24/7 for delivery anywhere in Sydney.

Do the Orange and Bathurst stores stock BMS?

Yes. Our Bathurst and Orange stores stock BMS. If a specific size isn’t available, we can source it quickly or transfer stock from another branch.

How much does BMS cost?

Pricing depends on the size (profile and dimensions) you need and the quantity. You can check live pricing anytime on our Edcon Steel online store or request a quote.

What is the minimum length I can buy?

We cut down to a minimum of 15 mm. Whether you need a short offcut or a full length, you can order exactly what you need.