Structural Steel Fabrication Services

Precision-made steel. End-to-end project support. All in-house.

At Edcon Steel, structural steel fabrication is more than just a process — it’s a complete, start-to-finish service built on over 50 years of experience. From a single custom bracket to multi-tonne, fully sequenced structural packages, our in-house Fabrication Department delivers what builders, engineers and project managers need: precision, coordination, and confidence on-site.

Our team works from your supplied engineering drawings or plans, cutting, welding, coating, and coordinating every element to spec, schedule, and standard.

Why Builders Choose Edcon

At Edcon Steel, we provide a fully coordinated structural steel solution—from quoting and detailing to fabrication, coatings, and delivery. Our experienced team handles every stage to ensure your project runs smoothly, your steel fits, and nothing is left to chance.

We specialise in structural steel fabrication for residential, commercial, and industrial builds across NSW. Our in-house Fabrication Department brings together estimators, drafters, welders, machine operators, and logistics coordinators — all working in sync to deliver accuracy, reliability, and peace of mind.

We’re set up for flexibility, whether you need a single beam or a staged multi-tonne steel package.

Our End-to-End Fabrication Workflow

1.Estimating

We begin with clear, accurate quotes tailored to your project scope. Our estimators break down pricing by item and specification, helping you assess costs and timelines with full transparency. This upfront clarity helps reduce delays and ensures everyone starts on the same page.

READ MORE

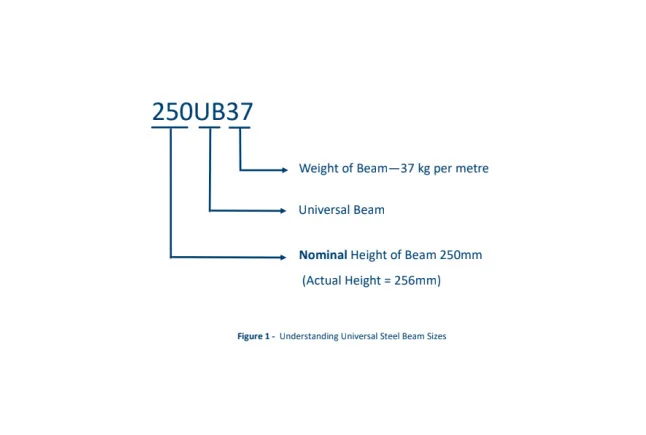

2. Drafting & Detailing

Once the scope is confirmed, we work from your supplied structural drawings or collaborate with trusted drafters to complete fabrication-ready files. We also support DXF file conversion and can coordinate with your engineer to resolve missing details. Every component is clearly marked, sized and mapped for fabrication.

READ MORE

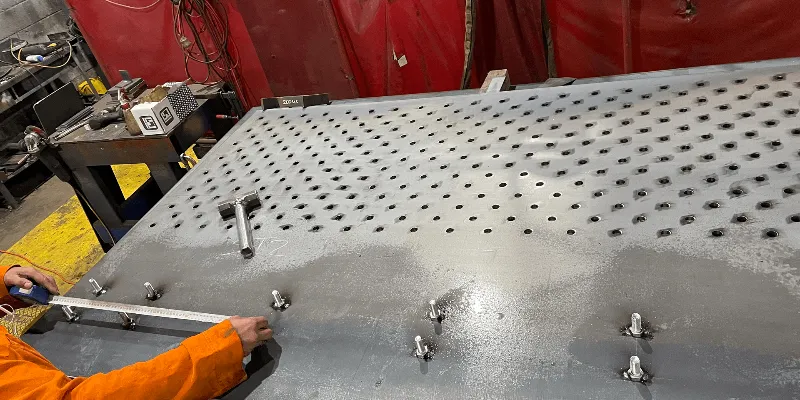

3. Processing & Fabrication

Steel is processed in-house using advanced cutting, drilling, and welding machinery. Our team fabricates beams, posts, frames, cleats and plates according to your exact specs. We check tolerances, confirm fit, and label components clearly, ready for either assembly or direct delivery to the site.

READ MORE

4. Surface Treatments

We apply protective coatings suited to your build environment. From shop priming and two-pack systems to hot-dip galvanising, every treatment is matched to the job, with corrosion resistance, durability and compliance top of mind.

READ MORE

5. Delivery or Collection

Fabricated steel is prepared for the site with coordinated delivery sequencing. We label each component for ease of installation and can work with your crane booking or install team to avoid downtime. We deliver across Greater Sydney, the Blue Mountains and the Central West — or you can click & collect from our yard.

End-to-End Project Examples

From small residential builds to complex, multi-stage installations — here’s how we deliver structural steel that performs in the real world.

Shore Grandstand 2

Full-service package including detailing, fabrication, and hased delivery.

Yarning Circle Project

Curved steel elements fabricated in-house and installed

on-site.

Mosman Residential Steelworks

Custom-fabricated steel for a complex residential project.

Tools, Services & Support

Explore coatings, welding services, and project insights that support every stage of your build.

Structural SteelStructural Steel Articles

Frequently Asked Questions

What are common reasons to use structural steel

Structural steel is strong, durable, cost-effective, and highly adaptable — making it ideal for everything from residential builds to large-scale commercial structures. It allows for fast fabrication, easy transport, and reliable performance under pressure. Steel also supports sustainable construction thanks to its recyclability and efficient use of material. Read the full article →

What structural steel components can Edcon Steel fabricate?

Edcon fabricates a wide range of structural components, including beams, columns, cleats, brackets, plates, posts, channels, and custom supports. All items are cut, drilled, and welded in-house to match your project’s exact specifications.

Can Edcon fabricate steel from my CAD files or DXF drawings?

Yes. We regularly work from DXF files, structural drawings, and CAD-based plans. We can also coordinate with your engineer or drafter to make sure the fabrication package is finished.

How long does structural steel fabrication take?

Lead times vary depending on complexity, materials, and project size. Simple items like posts and brackets may be ready in a few days, while full structural packages are scheduled in line with build phases.