Beginners Guide to Steel: High-Speed Steel (HSS)

Beginners Guide to Steel: High-Speed Steel (HSS)

In the latest instalment of our Beginners Guide to Steel, we cover high-speed steel (HSS). HSS has revolutionised how we shape, cut, and mould various materials, advancing industries from construction to aerospace.

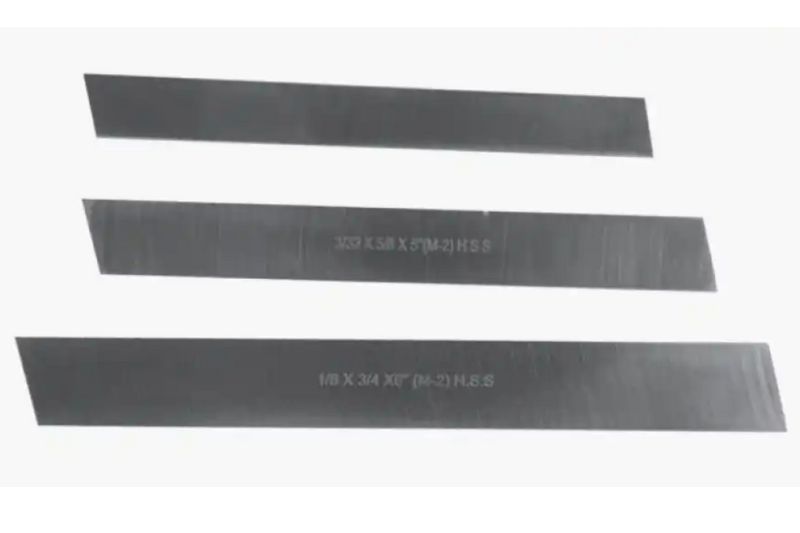

Edcon Steel now stocks a range of HSS, available online in our Engineering Steel Range or at our Edcon Steel Revesby store. Here, we cover the basics of this steel group, its characteristics, advantages and use in various applications.

What is HSS Steel?

HSS comprises a set of steel alloys named for their capacity to cut materials faster than traditional high-carbon steels previously used in cutting tools. HSS is renowned for its exceptional hardness, allowing it to retain a sharp cutting edge even at elevated temperatures. This property is crucial for maintaining precision and dimensional accuracy in machining and engineering operations.

The heat treatment used is also a major component of what defines HSS, as its martensitic structure contributes to its high hardness. This is achieved by austenizing to nearly the steel’s melting temperature, then quenching in a salt bath or by air cooling and multiple tempering cycles to convert any remaining austenite to martensite.

Though the term high-speed steel describes multiple alloys, these traits are common to all of them:

- High alloy content, primarily tungsten or molybdenum, with lesser amounts of chromium, vanadium and cobalt;

- High carbon content—a minimum of 0.65% by weight, but commonly anywhere from 0.8% to 1.5% carbon content;

- Rockwell hardness of at least 64 HRC at room temperature;

- A heat treatment process that produces a high quantity of complex metallic carbides—chiefly tungsten, molybdenum and vanadium carbides—suspended in a steel substrate, which results in hardness and wear resistance.

Benefits of High Speed Steel

In addition to its exceptional hardness, High-Speed Engineering Steel owes its exceptional performance to a combination of other key properties:

Heat Resistance: The alloying elements in HSS contribute to its remarkable heat resistance, enabling tools to withstand the high temperatures generated during cutting and shaping processes without losing their hardness or becoming deformed.

Wear Resistance: HSS exhibits excellent wear resistance, ensuring prolonged tool life and minimising the need for frequent replacements. This characteristic translates to lower production costs and increased efficiency for manufacturers.

Toughness: Despite its hardness, HSSl retains a degree of toughness, which prevents it from becoming brittle during operation. This toughness is essential for withstanding sudden impacts and vibrations commonly encountered in machining applications.

Versatility: HSS is highly versatile and can be used to machine a wide range of materials, including metals, plastics, and composites. Tools made of HSS frequently keep a sharp edge for longer than other carbon steels, and the variety of grades and surface treatments available provide options for specialised applications.

HSS Applications

HSS forms the backbone of cutting tools such as drills, end mills, taps, and reamers used in metalworking operations. Its ability to maintain a sharp edge at high speeds and temperatures ensures fast and precise machining of ferrous and non-ferrous metals alike. Despite the advent of advanced cutting tool materials such as carbide and ceramic composites, HSS continues to hold its own in many industrial applications. Its affordability, ease of fabrication, and proven performance make it a preferred choice for manufacturers worldwide.

HSS blades and cutters are widely employed in woodworking applications, including saws, planers, and routers. The hardness and wear resistance of HSS enables these tools to withstand the abrasive nature of wood and deliver clean, accurate cuts over prolonged periods.

HSS is also used to manufacture moulds and dies for plastic injection molding and die casting because it can maintain intricate geometries and surface finishes. Its superior heat resistance ensures minimal thermal deformation during prolonged moulding cycles.

HSS also plays a vital role in producing critical components for the automotive and aerospace industries, including engine parts, transmission gears, and aircraft structural elements. Its combination of hardness and toughness makes it ideal for machining complex shapes and profiles with tight tolerances.

Buy steel online. Delivery or In-store pick up.

At Edcon Steel, we’re your one-stop shop for steel. Over the last 50+ years, we’ve built a reputation as the steel experts with the biggest range and best service.

Available for a quote and online purchase 24/7, you can browse over 2,000 steel products. Plus, most of our stocked products can be custom-cut to your requirements, so you only pay for what you need.

Browse our online steel store to find the right engineering steel or metal for your next project.