Copper Price Increase Explained (And How It Affects Brass and Bronze)

Copper prices in Australia have risen sharply since mid to late 2025, affecting a wide range of industries. These price increases are not unique to Australia, nor are they driven by local suppliers. Copper is one of the most sought after metals in the world, and as a globally traded commodity,its price is influenced by international supply and demand, geopolitical events, energy costs, and major economic trends. When global copper prices rise, Australian buyers feel the impact almost immediately.

Understanding why copper prices have increased, how this affects alloys like brass and bronze, and what suppliers such as Edcon Steel are doing to support customers can help businesses and individuals plan projects more effectively during a volatile period.

What’s Driving the Increase in Copper Prices?

The rise in copper prices since has been driven by several overlapping global factors.

Supply disruptions at major mines, including flooding, equipment failures, safety incidents, labour disputes, and planned maintenance shutdowns. When large copper mines reduce output, global supply tightens very quickly.

Reduced smelting capacity, particularly in China, where some copper smelters have cut production due to higher operating costs and lower profit margins. This limits the amount of usable copper available to the market.

Strong global demand, driven by large-scale investment in infrastructure, renewable energy, electric vehicles, and electrification projects, all of which rely heavily on copper.

A rebound in manufacturing activity across many regions, increasing copper consumption at a time when supply is already constrained.

Lower global copper inventories, as demand has outpaced production, making the market more sensitive to any supply or demand changes.

Optimism around US–China trade relations, which has boosted confidence in global manufacturing and infrastructure investment. Even the possibility of easing trade tensions has encouraged buyers and investors to secure copper in anticipation of stronger economic growth.

Rising energy and transport costs, with higher diesel, electricity, and freight prices increasing the cost of mining, refining, and transporting copper throughout the supply chain.

Together, these factors have created a tight global copper market, leading to sustained price increases rather than short-term fluctuations.

Browse Edcon’s range of metal

How Rising Copper Prices Affect Brass and Bronze

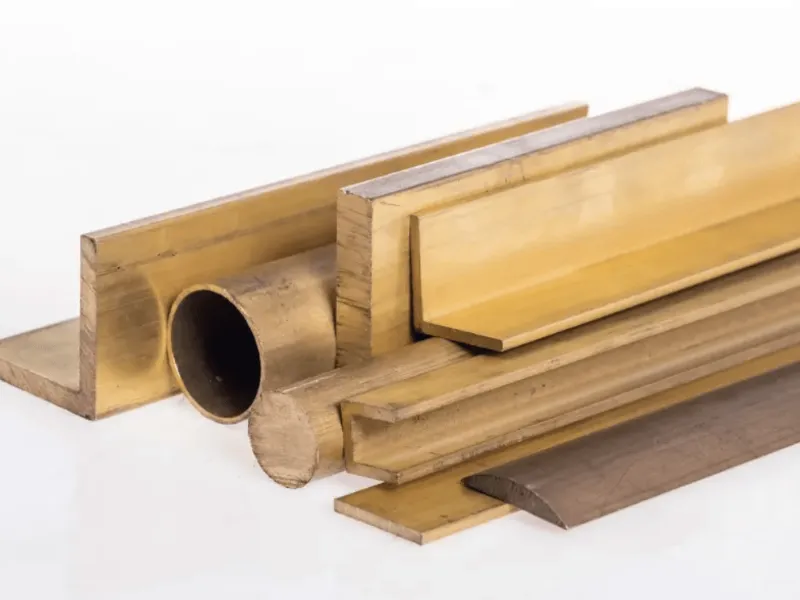

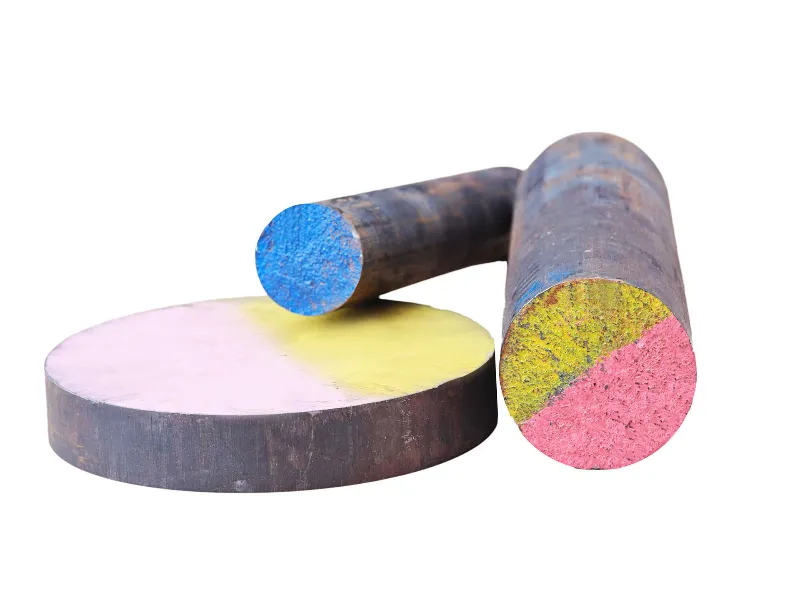

Brass and bronze prices in Australia have increased alongside copper because both alloys contain a high percentage of copper.

Brass typically consists of around 60 to 70 per cent copper, combined mainly with zinc. Bronze usually contains even more copper, often between 85 and 90 per cent, with tin as the primary secondary metal.

Because copper makes up the majority of these alloys, changes in copper prices directly affect the cost of producing brass and bronze. When copper prices rise, manufacturers face higher raw material costs, which are passed through to suppliers and customers.

This impacts a wide range of products, including brass plumbing fittings, valves, rods, sheets, and decorative components, as well as bronze bearings, bushings, bars, plates, and architectural elements. Even recycled brass and bronze become more expensive when copper prices are high, reinforcing the upward trend.

For Australian buyers, this means that price increases are often unavoidable across all copper-containing materials, even for relatively small components.

Impact on Australian Builders, Trades, and DIY Projects

Higher copper prices affect many industries across Australia.

Electricians face increased costs for copper wiring and cabling. Plumbers see higher prices for copper pipe and brass fittings. Builders and contractors must account for rising material costs when quoting jobs, particularly for larger projects or long-term contracts.

Manufacturers and fabricators using copper, brass, or bronze are also impacted. Increased material costs can reduce margins and require price adjustments, especially where contracts were priced before the recent increases.

DIY enthusiasts and home renovators feel the impact as well. Whether it’s a renovation, a custom fabrication project, or general maintenance, higher prices for copper-based materials can quickly increase overall project costs.

Although Australia produces copper domestically, local pricing is still tied closely to global markets. This means international conditions directly influence copper, brass, and bronze prices throughout New South Wales and the rest of the country.

How Edcon Steel Is Supporting Customers

Edcon Steel understands the challenges that rising copper prices create for customers across NSW and Australia. While global metal prices are outside local control, Edcon Steel focuses on reducing the impact wherever possible.

Clear communication is a priority. Edcon works to explain market conditions and pricing changes so customers can make informed decisions and plan ahead.

Where possible, Edcon Steel delays passing on price increases, absorbing higher costs for as long as it is commercially viable. This helps smooth sudden price movements and provides greater stability for customers.

Careful stock management and bulk purchasing also help reduce exposure to short-term market volatility. Holding inventory purchased at earlier prices can sometimes limit immediate increases, depending on availability.

Edcon Steel’s custom cutting is particularly valuable during periods of high prices. By supplying materials cut to exact requirements, customers can avoid unnecessary waste and reduce costs, especially when working with copper, brass, or bronze.

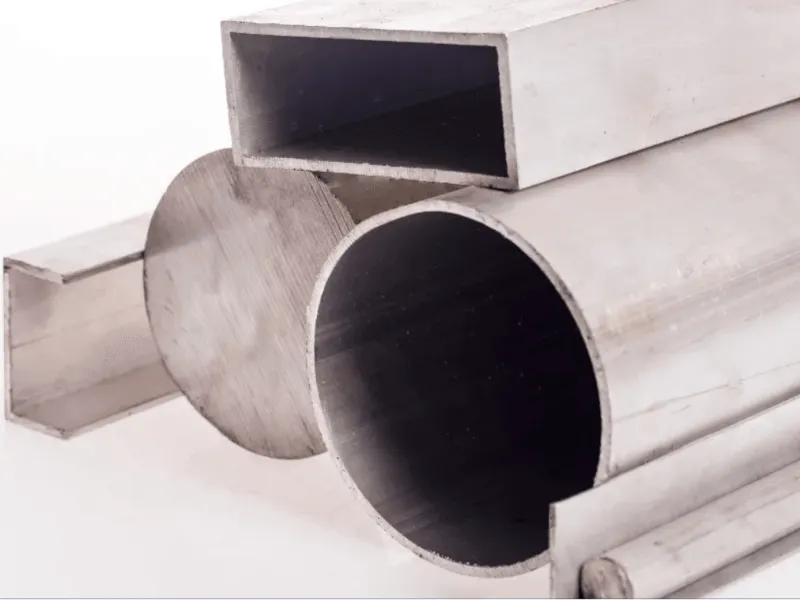

The team at Edcon Steel can also help customers explore alternative materials where appropriate. In some applications, stainless steel or aluminium may provide a suitable and more cost-effective option, depending on the project requirements.

Above all, Edcon Steel remains committed to fair pricing and long-term relationships with builders, tradespeople, and DIY customers across NSW, including Brookvale, Revesby, Blacktown, Bathurst, and Orange, as well as nationwide delivery.

For Australian customers, staying informed and planning ahead is essential. Working with an experienced supplier like Edcon Steel provides access to reliable stock, expert advice, and services designed to minimise waste and manage costs.

While we can’t control global copper prices, we remain committed to supporting customers with transparency, efficiency, and practical solutions.

Talk to the Team at Edcon Steel

Planning a project that uses copper, brass, or bronze? Speak with the team at Edcon Steel for up-to-date pricing, cut-to-size options, and expert advice to help you manage costs and plan with confidence.

Frequently Asked Questions

Which Edcon Steel locations stock copper and copper alloys?

Copper, brass, and bronze products are available at all Edcon Steel stores (Brookvale, Revesby, Blacktown, Bathurst, and Orange), including our online store.

Are copper price increases the same across all NSW suppliers?

Generally yes. Copper is traded internationally, so NSW suppliers source material at similar global prices. Local suppliers like Edcon Steel do not control the base copper price.

How is Edcon Steel helping NSW customers manage copper price volatility?

Edcon Steel focuses on transparent pricing, delaying increases where possible, and offering cut-to-size services so NSW customers can reduce waste and control project costs.

Can I buy smaller quantities of copper or brass at Edcon Steel?

Yes. Edcon Steel’s custom cutting service allows customers across Australia to purchase only the amount of copper, brass, or bronze they need.

Does Edcon Steel supply copper products outside Sydney?

Yes. Edcon Steel supplies copper, brass, and bronze through locations in Sydney and regional NSW, including Brookvale, Revesby, Blacktown, Bathurst, and Orange, with nationwide delivery also available.

Can Edcon Steel advise on alternatives when copper prices are high?

Yes. Edcon Steel’s team can help assess whether materials like stainless steel or aluminium may be suitable alternatives, depending on the application. While we can offer advice, always confirm your specific requirements and compliance needs with a qualified engineer or builder, especially for structural applications. This ensures your project is safe and meets all regulations before you build.

How can I get current copper, brass, or bronze pricing in NSW?

You can view live pricing and stock availability on our website or request a quote from your nearest store. Prices vary based on size, material grade and finish. We sell by the length you need, so you only pay for what you use.