Understanding the Different Types of Steel

Steel is the bedrock of Australia’s construction, manufacturing, and engineering industries. But not all steel is created equal. Each project or application demands a specific type of steel with particular properties and characteristics.

At Edcon Steel, we offer a wide range of steel products tailored to meet the specific demands of every project. Here, we examine five of our key categories of steel: mild steel, structural steel, stainless steel, engineering steel, and tool steel. Learn about their composition, strengths, and ideal uses so you can make an informed buying decision.

Browse Edcon’s range of Steel

Mild steel: The workhorse of general fabrication

Mild steel, or low-carbon steel, is affordable and versatile. It is easy to work with and is used in everyday fabrication, with excellent weldability, high ductility, and formability.

Mild steel is generally more affordable than many other steel types, making it a popular choice for budget-conscious projects. However, it can be more susceptible to rust, so it often requires protective coatings or surface treatments to enhance its longevity and prevent corrosion.

Typical Applications

- Automotive panels

- Furniture and framing

- Fencing and gates

- General fabrication work

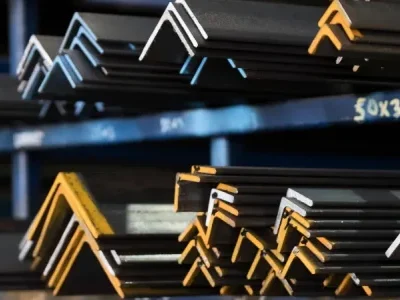

Structural Steel: Strength and Stability

Structural steel offers a superior strength-to-weight ratio, making it ideal for buildings, bridges, and large frameworks. It provides structural integrity without excessive bulk and is highly ductile, perfect for withstanding dynamic forces like wind and earthquakes. Structural steel is highly durable and consistent under stress.

Typical applications

- Beams and columns

- Industrial platforms and walkways

- Bridges and heavy frameworks

Stainless steel: corrosion-resistant and visually appealing

Stainless steel stands out for its corrosion resistance and smooth, polished finish. It is ideal for environments exposed to moisture or where hygiene and appearance matter, like kitchens, hospitals, and marine settings. While there are several grades of stainless steel, 304 and 316 are the most commonly used.

Popular Uses

- Kitchen and food-grade equipment

- Handrails and balustrades

- Marine hardware

- Surgical and medical tools

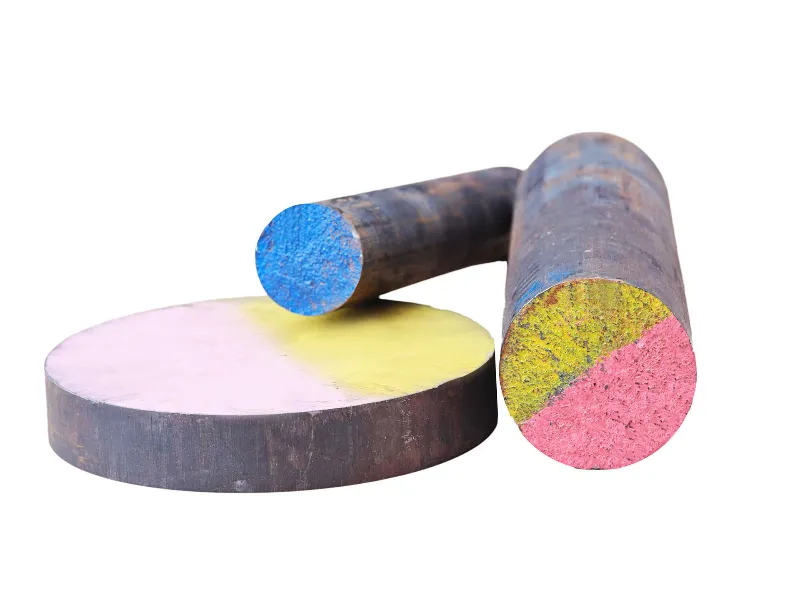

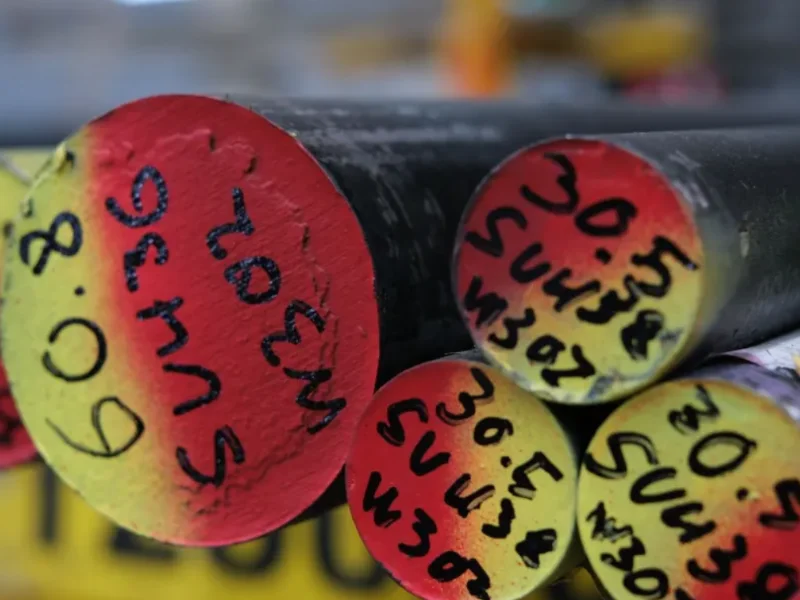

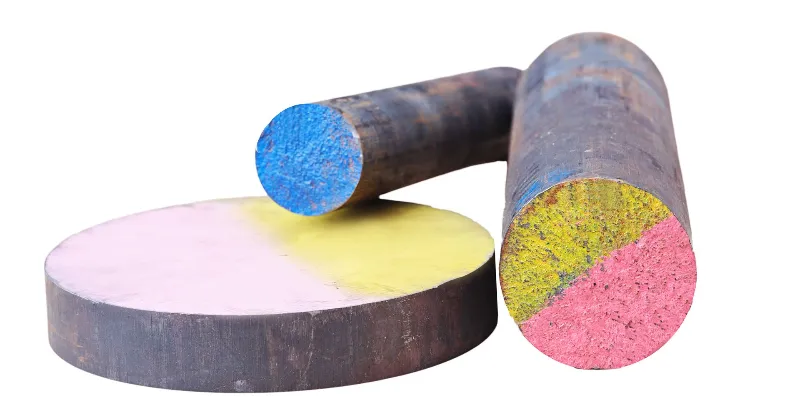

Engineering Steel: For Precision and Performance

Engineering steel refers to a family of carbon and alloy steels with controlled chemical compositions for enhanced mechanical properties. These steels are used in manufacturing components that demand strength, fatigue resistance, or specific heat treatment capabilities.

Edcon Steel offers a wide range of engineering steels that meet the needs of diverse industries — from construction to automotive and heavy machinery.

Common Engineering Steel Types:

- Mild Steel (e.g. Grades 1020, 1030): Versatile, low-carbon steels that are easy to weld and machine. Suitable for light structural applications and general fabrication.

- Medium Tensile Steel (e.g. Grade 1045): This steel offers higher strength and hardness than mild steel and is used for axles, gears, and bolts.

- High Tensile (e.g. Grades 4140, 4340) Steel: A popular choice for high-stress components due to its excellent fatigue strength and hardenability.

Key Properties

- Higher tensile and yield strength

- Improved hardness and wear resistance

- Suitable for heat treatment

- Good machinability and dimensional stability

Common Applications

- Shafts and axles

- Gears and couplings

- Pins, bolts, and spindles

- Precision-machined components

Tool Steel: Designed for Tough Jobs

Tool steel is a type of engineering steel specially formulated to retain hardness and wear resistance even under extreme conditions. It is engineered specifically for tool-making applications and is used in tools, dies, moulds, and cutting applications where high precision and durability are required.

They offer exceptional hardness, abrasion resistance, and the ability to retain a cutting edge, which are essential for punching, forming, cutting, and moulding.

Examples of Tool Steel Grades Offered by Edcon:

- O1 Oil-Hardening Tool Steel: Known for its outstanding dimensional stability and machinability. Ideal for cutting and stamping tools.

- D2 High Carbon, High Chromium: This material has excellent wear resistance and compressive strength and is often used in dies and industrial knives.

- H13 Hot Work Tool Steel: Designed to withstand high temperatures, making it perfect for extrusion dies, forging tools, and hot shear blades.

Common Applications

- Cutting tools and drill bits

- Dies and moulds

- Punches and blades

- High-wear machine parts

Buy online from Edcon Steel

At Edcon Steel, we pride ourselves on our level of customer service, our extensive product range, and the depth of our local market knowledge.

You can visit our stores to browse the range or pick up an online order. Our staff are on hand to answer any questions you have about our full range of products and services, so feel free to contact us for your steel or metal solution today.

FAQs

What types of steel are offered by Edcon Steel?

We offer five primary steel categories: mild steel, structural steel, stainless steel, engineering steel, and tool steel, each tailored for specific performance and application needs.

What is the best steel type for general-purpose fabrication?

Mild steel is ideal due to its low cost, ease of welding, ductility, and formability. It’s widely used in automotive panels, fencing, and furniture.

What type of steel is best for high-precision components or machinery parts?

Engineering steel is best suited for precision and performance applications. Its controlled chemical composition and heat-treatment capability make it ideal for parts like shafts, spindles, gears, and couplings.

What’s the difference between engineering steel and tool steel?

Engineering steel is used in high-performance components requiring strength and fatigue resistance, such as shafts and gears. Tool steel, on the other hand, is specially formulated for tool-making and cutting applications, retaining hardness even under intense conditions.

What grades of tool steel does Edcon Steel supply?

Edcon Steel supplies tool steel in several grades, including: O1 (Oil-hardening, dimensional stability), D2 (High wear resistance), and H13 (Hot work, heat-resistant), suitable for various cutting, stamping, and forging applications.