Hot Dip Galvanised vs Pregal Steel: What’s the Difference?

We have had many customers come into our store asking for “galvanised steel”, without realising that not all galvanising is the same. While galvanising steel is important in Australia, where the climate can be tough on steel, different applications require different galvanised steels.

Hot-dip galvanised steel and pre-galvanised steel (commonly known as pregal) are the two most commonly used types of galvanised steel. Both hot dip and pregal steel are used widely across industry and in everyday applications. But what exactly is the difference between the two? And which one should you choose for your project?

Here, we revisit the coating processes and characteristics of hot-dip galvanised steel and pregal steel, and break down the differences, so that you can choose the right product for your project.

What is galvanising?

Galvanising of Steel items is a coating process that involves applying a protective layer of zinc to steel to prevent rust. Zinc is used in galvanising because it corrodes before iron, acting as a shield between the steel and the environment, particularly moisture and oxygen.

Browse Edcon’s range of Structural Steel

What is hot-dip galvanised steel?

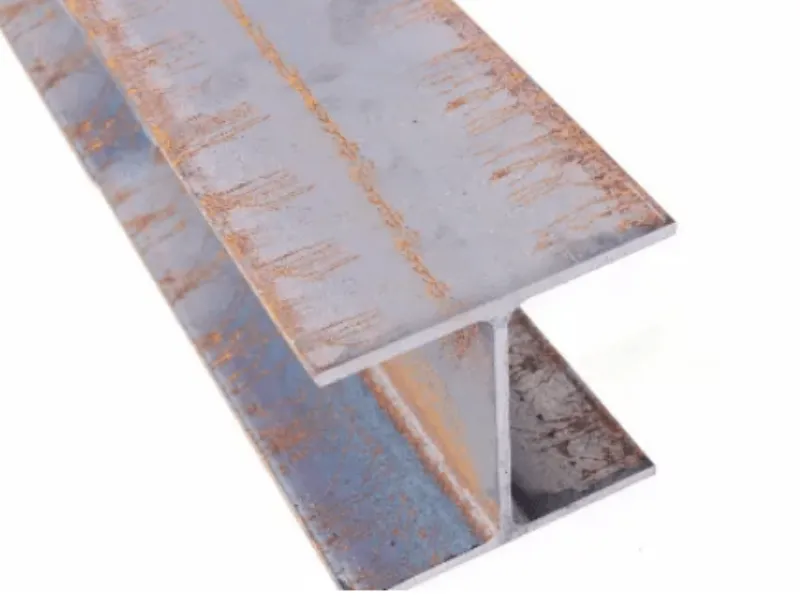

Hot dip galvanised steel has been through a galvanising process that involves dipping fully fabricated steel products (e.g. pipes, brackets, or beams) into a bath of molten zinc. As the entire product is submerged, the zinc bonds to all surfaces, including edges, corners, and internal recesses.

At Edcon, we cut the mill finish steel or stock length before sending it to our galvanisers (which typically takes 5-8 working days in the Sydney Metro area).

NOTE: Edcon Steel also stocks some Hot Dip Gal products in full lengths. When cut, these lengths do not have a galvanised end.

Benefits of hot-dip galvanised vs Pre-Gal finishes:

Higher protection: Because hot dip products are coated after manufacturing, every part of the product is covered, even welds, joints and threads.

Thicker coating: Hot dip galvanising generally includes a zinc layer between 70 and 100 microns, which offers outstanding corrosion resistance, particularly in coastal and rural Australian environments.

Longer lifespan: Hot-dip galvanised steel can last 20–50 years or more (depending on exposure conditions).

Disadvantages of hot-dip galvanised vs pre-Gal Finishes

Higher cost: The process is more intensive and typically comes at a higher cost.

Heavier finish: Because of the thicker coating, hot-dip galvanised is slightly heavier (up to 7%) and may have an uneven, less smooth and dimpled finish compared to pre-galvanised steel.

What is Pregal steel?

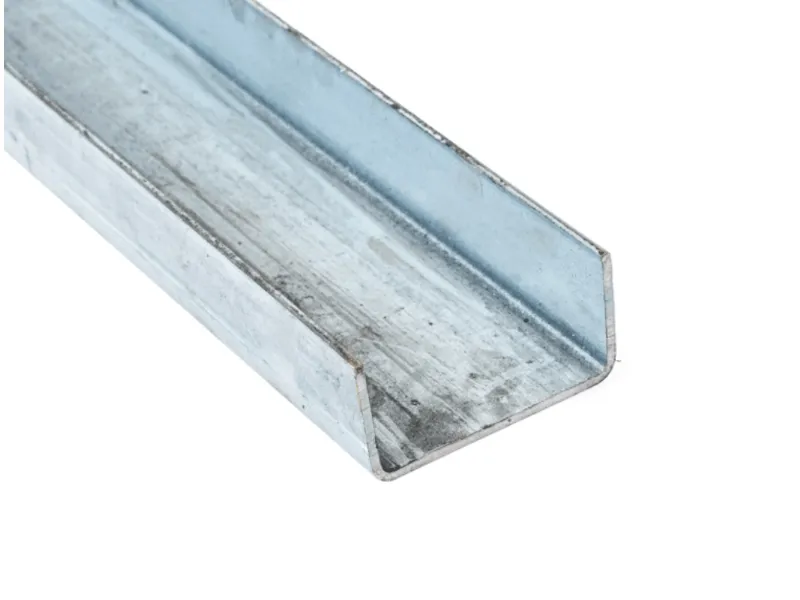

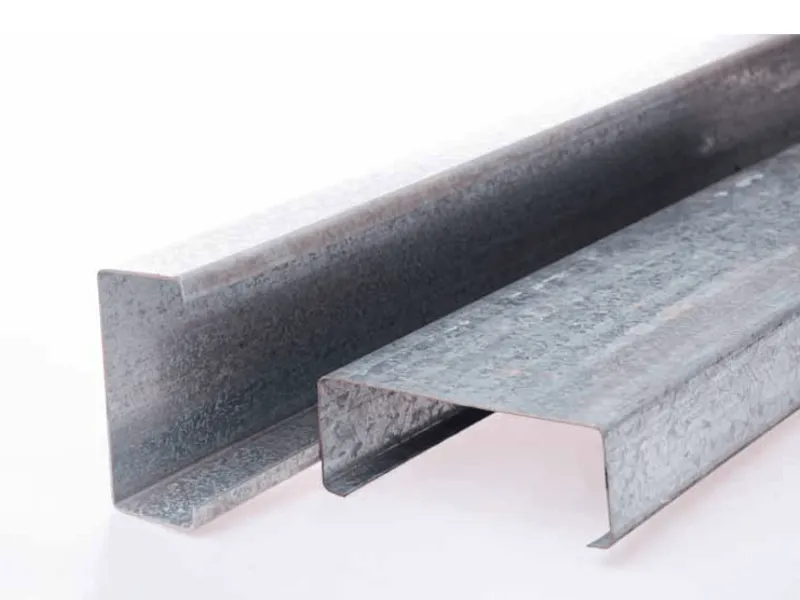

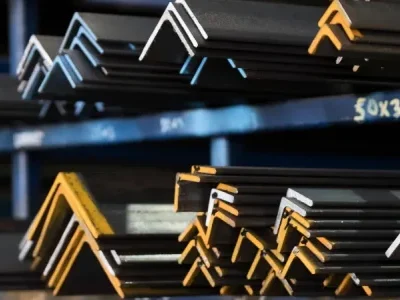

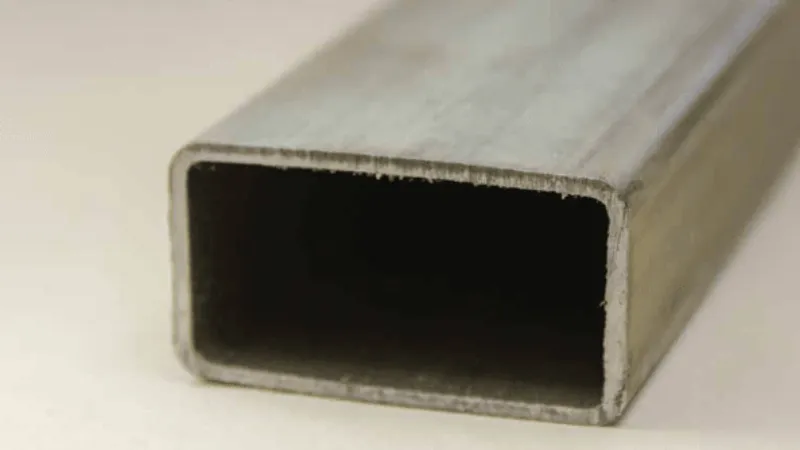

Unlike hot-dip galvanised steel, pregal steel is galvanised before it’s formed into a product. Steel coils or sheets are run through a continuous galvanising line, where it is dipped in molten zinc before being cut and shaped into products like flats, angles, SHS & RHS (square or rectangular hollow sections).

Benefits of pregal steel

More economical: Pregal steel is generally more cost-effective due to the efficiency of mass production.

Smoother appearance: Pregal steel generally has a more uniform and clean finish, making it popular in architectural or aesthetic applications.

Perfect for indoor use: Because of its smoother appearance and lighter finish, pregal steel works well in milder environments where extreme corrosion protection isn’t required.

Disadvantages of pregal steel

Weaker protection on edges and welds: Cutting and welding the steel after galvanising can expose untreated steel to the elements, leaving vulnerable points for rust.

Thinner coating: The zinc layer on pregal steel is typically 10–30 microns, making it less suitable for harsh or coastal conditions.

Which galvanised steel is right for you?

In a country like Australia, where we face a wide range of weather conditions, understanding the right steel to use can save you from headaches and unnecessary costs.

When deciding which type of galvanised steel is right for you, it all comes down to your application, environment, and budget.

We have provided a basic guide below, but you must talk to your builder, certifier, architect, or engineer before purchasing to clarify what you need. Edcon Steel staff can’t recommend which product to use.

| Application | Typical Steel type |

| Outdoor/coastal projects | Hot-dip galvanised |

| Structural applications | Hot-dip galvanised |

| Farm gates and fencing | Hot-dip galvanised |

| Garden sheds | Pregal (with care) |

| Roofing & gutters | Pregal (with coatings) |

| Aesthetic applications | Pregal |

| Indoor use (e.g. wall framing) | Pregal |

Buy online from Edcon Steel

At Edcon Steel, we pride ourselves on the expertise of our staff, our level of customer service and the depth of our local market knowledge.

You can visit our stores to browse the range or pick up an online order. Our staff are on hand to answer any questions you have about our full range of products and services, so feel free to contact us for your steel or metal solution today.