Handmade Kaleidoscope

What can’t our customers do?

When we heard about this handmade kaleidoscope by Steve Matheson and his son Brendan, we knew we had to share it with the wider Edcon Steel community.

Steve and Brendan wanted to take on a new project to spend some quality time together and thought a project of some sort would be perfect.

“As father and son, we’ve often done little projects together, but this is the first major project we’ve done together,” Steve explains.

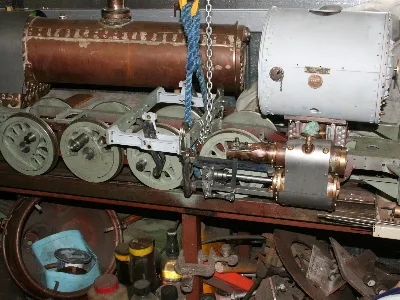

Created using brass, flat bar, square bar and bronze, this masterpiece is not just exquisite to look at, but magnificent to look through!

The inspiration

When we asked why Steve decided on a kaleidoscope specifically, he replied: “Just a moment of craziness, I think.

I know how much kids love kaleidoscopes and I thought, ‘wouldn’t it be fun to do that and make it big!’”

The undertaking is even more impressive when considering that the father-son duo didn’t use a guide.

“We didn’t use plans,” Steve explains.

“We just did some research about how kaleidoscopes work, and once we worked out the mirror patterns, everything else just came out of our heads.”

Sourcing materials

Aside from a few recycled parts, they purchased all the brass used in the project from the Edcon Steel Revesby store.

“We used brass hex stock of various sizes for the supporting rail and handle,” says Brendan.

“For the kaleidoscope barrel, we used 25mm and 30mm flat bar, and 25mm square bar for various machined parts.

We also used some bronze, as bearings for turning components and the tilting mechanism.”

Using brass was a stylistic and functional choice, as Brendan explains: “We wanted to use copper-based products to suit the steampunk theme and overall look.

The soft metals are also forgiving as we learned how to use the lathe and milling machines I had purchased.

The team at Edcon Steel were so helpful and allowed us to pick through their expansive supply of non-ferrous metals.”

“The friendly staff had a good laugh with us over our crazy ideas during the build.”

Steve went on to explain that Edcon Steel has been his local supplier because of the convenience and the service.

“The guys there are so good,” he explains.

“They are really helpful. But I think they thought we were a bit mad!”

The project

The project, which took around 18 months to complete, involved a great deal of learning.

Not only did Steve and Brendan learn how kaleidoscopes actually work, but with little to no metalworking experience, Steve learnt how to braze, mill and lathe!

“Brendan taught me so much stuff,” Steve says.

“He taught me how to braze because he’s a plumber and really good at that.”

“And together we learnt how to use a mill and a lathe. So it was a lot of time learning from each other, which did us both a world of good. It was pretty fantastic really.”

The process involved a lot of research, and a lot of trial and error.

“We made a few bits that didn’t work, which we had to throw away and start again,” Steve says.

“With the gear system and the pins, which allows you to crank the handle to turn the barrel, that just involved sitting down and really nutting out what we needed to do logically.”

The finished product

Steve, an active member of his local community, takes the kaleidoscope to community events with the East Hills District Men’s Shed, of which he is the secretary.

“We take it to local events, like charity nights, and we use the money raised to support local charities and organisations, like the Revesby women’s shelter.”

Hoping to take the kaleidoscope out for more people to enjoy, Steve is thinking about attaching wheels to make it easier to transport. If you have an event coming up in the Revesby area and would like Steve to bring his kaleidoscope along, please get in touch with the East Hills District Men’s Shed.

Are you starting a DIY project?

At Edcon Steel, we pride ourselves on our level of customer service and the depth of our industry knowledge. Our experienced staff will provide insight and support on all of our steel, metal and industrial products.

Whether you are in-store to browse the range or to pick up an online order, our staff are on hand to answer any questions you have about our full range of products and services, so feel free to contact us for your steel or metal solution today.