Steel Sheet and Plate 101: Understanding Types, Uses, and Options at Edcon Steel

When it comes to building, fabricating, or even tackling weekend DIY projects, steel sheet and plate are two of the most versatile and widely used materials around. Whether you’re making a bracket, building a base plate, or repairing a trailer floor, there’s a steel product that fits the job perfectly.

At Edcon Steel, we stock a wide range of steel sheet and plate, with options to suit various applications, from light fabrication to heavy industrial work. But what exactly are steel sheet and plate, and how do you know which one to use? Let’s break it down.

Please note that all information provided is general in nature, and each reader is responsible for checking with the manufacturer/specifier or engineer before relying on any information provided.

What is Steel Sheet and Plate?

Although often used interchangeably, “sheet” and “plate” refer to flat steel products of different thicknesses. A steel sheet is a thinner material, usually 3mm thick or under. It’s often produced in coils and then cut into flat pieces. Steel plate, on the other hand, typically starts at around 4mm thick and increases from there, cut from heavy plate material.

Both are made to strict Australian Standards and serve a wide range of applications, from roofing and cladding to load-bearing structures and machinery bases.

One of the most significant advantages of buying through Edcon Steel is flexibility: You don’t have to buy a full standard sheet if you don’t need it. We offer custom cutting on all steel sheet and plate products, meaning you can order exactly what you need—no waste, no extra cost.

Browse Edcon’s range of Sheet and Plate

What’s the Difference Between Hot-Rolled and Cold-Rolled Steel?

Once you know whether you need sheet or plate, the next step is choosing between hot-rolled and cold-rolled steel. The main difference comes down to how the steel is processed and the surface finish or precision required.

Cold-rolled steel is typically less than 1.2 mm thick and is rolled at room temperature after the initial hot rolling. This gives it a smooth, uniform surface and more precise dimensions. Cold-rolled sheet is ideal when you need a clean finish for painting, powder coating, or appearance — it’s commonly used for automotive body work steels for panel repairs or restoration.

Hot-rolled steel is typically over 1.6 mm thick and is rolled at high temperatures, resulting in a rougher, slightly scaled finish. While not as refined as cold rolled, it’s easier to work with for cutting, welding, and forming. It’s the go-to option for structural projects, framing, base plates, and general steelwork where surface finish isn’t critical.

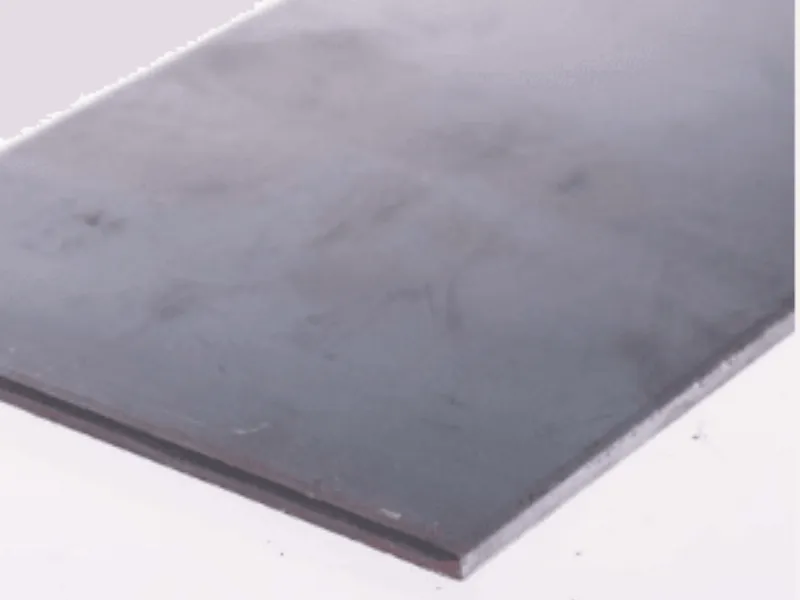

Mild Steel Sheet & Plate (Grade 250)

For general-purpose steelwork, Grade 250 mild steel sheet and plate is the go-to material across Australia. It’s the classic, reliable choice for builders, fabricators, and tradespeople alike.

Key Features

Yield Strength: Minimum 250 MPa (megapascals)

Composition: Low-carbon steel (around 0.05–0.25% carbon)

Properties: Easy to cut, weld, and machine

Mild steel is known for its versatility and affordability. It’s strong enough for most structural and fabrication applications, yet soft enough to be shaped or drilled with ease. Because it’s low in carbon, it doesn’t harden easily during cutting or welding—making it a dream for fabricators. The only trade-off is that mild steel will rust if left unprotected. Fortunately, it accepts paint and coatings very well, allowing for a long-lasting protective finish.

Common Uses

-Structural frames

-Base plates and brackets

-Steel tanks and supports

-General fabrication and repairs

At Edcon Steel, Grade 250 sheet and plate come in a wide range of thicknesses, and our team can cut to your exact dimensions.

Grade 350 Sheet and Plate

When you need extra muscle, Grade 350 sheet and plate step up.

Key features:

Yield Strength: Minimum 350 MPa (megapascals)

Composition: Low-carbon steel (around 0.14–0.22% carbon)

Properties: Good formability and weldability

Grade 350 steel sheet and plate is known for its formability and weldability. While it has a higher strength-to-weight ratio than mild (250 grade) steel (approximately 40% stronger), it remains easy to work with.

Common uses

-Building frameworks and gussets

-Bridge construction

-Vehicle chassis and trailers

-Storage tanks and lifting lugs

Galvanised and Zincanneal Sheets

When corrosion is the enemy, galvanised steel is your best friend. At Edcon, we stock two main types of corrosion-resistant coated sheet steel: Galvabond and Zincanneal, both manufactured by BlueScope Steel.

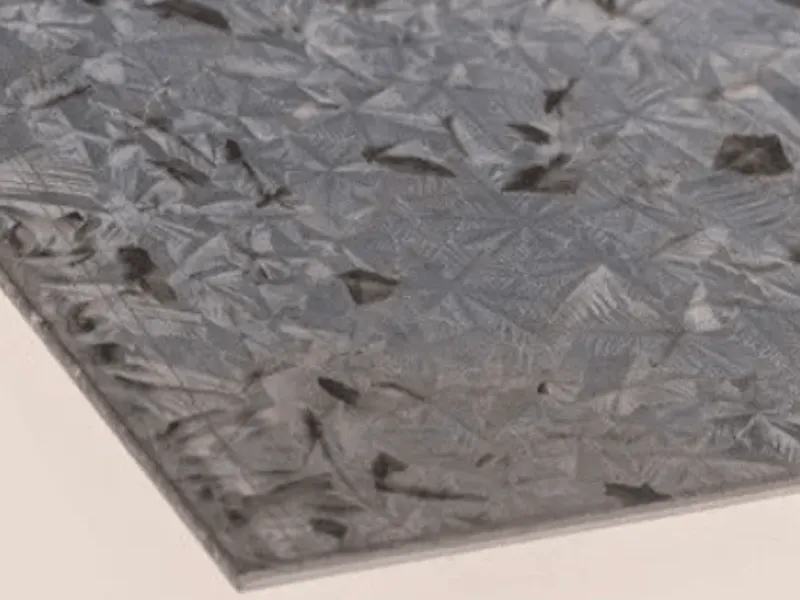

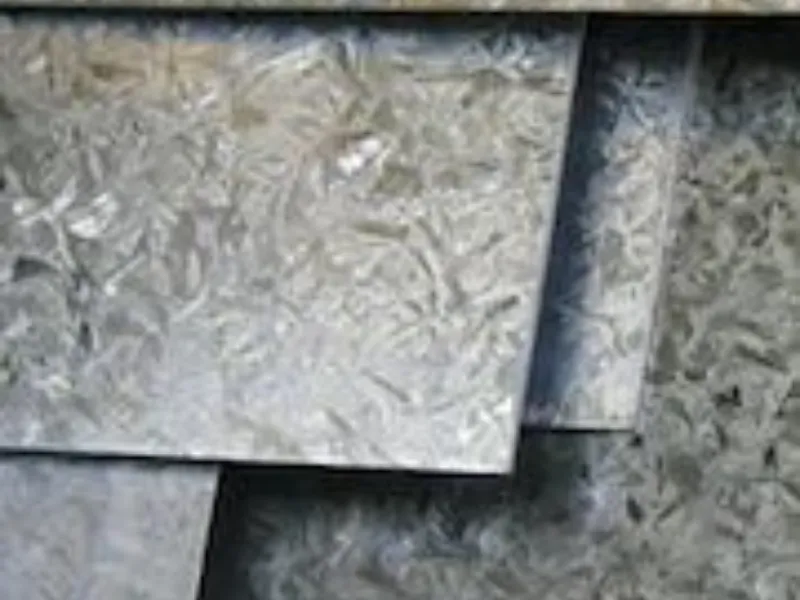

Galvabond® Sheet

Galvabond is the classic hot-dip galvanised steel sheet. Its base steel is coated in a layer of zinc for corrosion protection, and the shiny, spangled surface is instantly recognisable.

It is best for outdoor or exposed projects such as toolboxes, sheds, ducting, and panels.

Key features:

-Excellent corrosion resistance

-Can be bent and folded without cracking

-Ideal for use without additional paint

However, freshly galvanised surfaces can be tricky to paint, so if you plan to topcoat your steel, Zincanneal might be the better choice.

Zincanneal® Sheet

Zincanneal starts as galvanised steel but undergoes an annealing process that forms a zinc-iron alloy layer on the surface. The result? A smooth, matte grey finish that’s perfect for painting.

It is best for indoor, painted, or aesthetic applications such as appliances, cabinets, and door frames.

Key features:

-Paints easily (no special prep needed)

-Great formability and weldability

-Ideal for post-fabrication finishing

Important: Zincanneal should always be painted if used outdoors, as it doesn’t have the same long-term rust protection as Galvabond.

At Edcon Steel, both Galvabond and Zincanneal sheets are available in various thicknesses (typically 0.6–3 mm) with standard Z275 coating weight, offering strong, reliable protection. And, as always, we’ll cut your sheet to size while you wait.

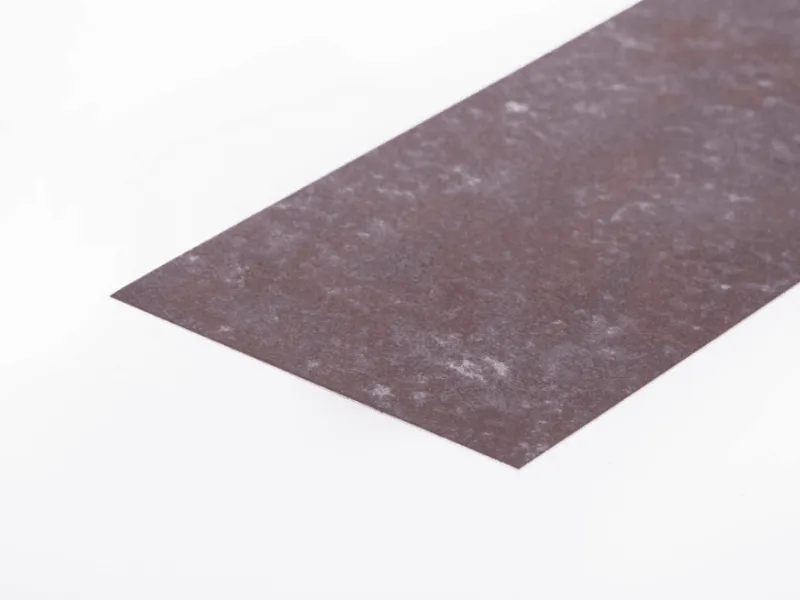

Corten (Weathering) Steel Plate

Corten steel, also known as weathering steel, is both beautiful and practical. Corten is an American Brand name, and the Australian-made product is Redcor, formerly called Lyten. If it is imported, it is under the WR350 grade.

Corten (BlueScope WR350 grade) is designed to form a protective, rust-like patina and is intended to last without the need for paint or coating. While it is NOT rusty at the point of purchse, it develops a stable oxide layer when exposed to air and moisture after 3-6 months. This patina protects the underlying steel, eliminating the need for painting and giving the material its signature warm, rustic look.

Popular Applications

-Architectural facades and sculptures

-Garden edging and landscaping

-Bridges and outdoor structures

-Decorative panels and art installations

Corten performs best in environments with wet/dry cycles, so it’s unsuitable for constant water immersion. When used correctly, it’s low-maintenance, long-lasting, and visually stunning. Edcon’s WR350 weathering plates are stocked in standard sizes (e.g., 3 mm x 1200 x 2400 mm) and can be cut to order.

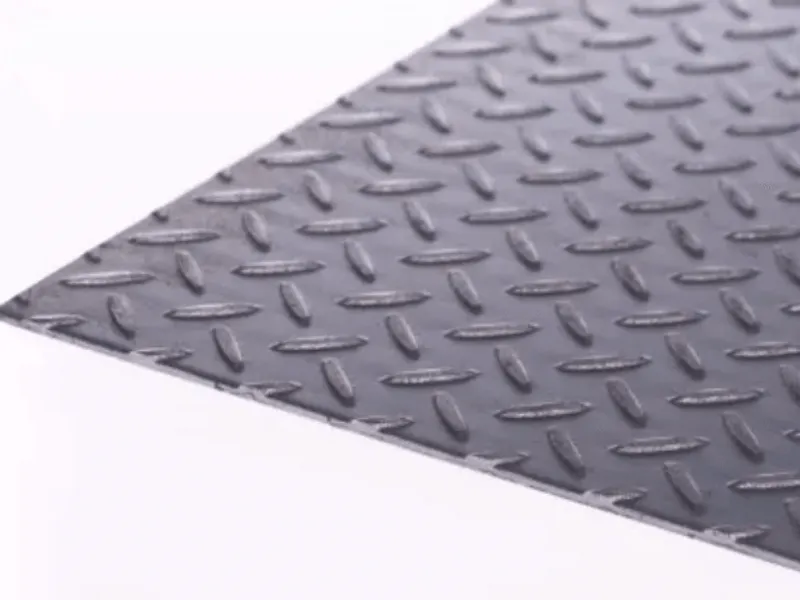

Chequer (Tread) Plate for Anti-Slip Surfaces

If safety and durability are top priorities, chequer plate, also called tread plate or floor plate, is the solution.

This steel plate features a raised diamond or five-bar pattern on one side, providing excellent traction underfoot. Made from Grade 250 mild steel, it’s tough, wear-resistant, and ideal for high-traffic or heavy-use areas.

You’ll often find it on stair treads and catwalks, ramps and workshop floors, ute trays, tuck beds, trailers, and industrial and commercial flooring.

Checker plates aren’t just functional; they’re also used decoratively for an industrial aesthetic, such as on bar fronts or wall panels. Edcon’s checker plates range from 2.1 mm to 12 mm thick, and we offer both mild and galvanised options depending on your environment.

Looking for quality steel sheet and plate in Australia?

At Edcon Steel, we supply cut-to-size steel to builders, tradies, and DIY enthusiasts across Sydney, NSW, and Australia-wide. From mild steel and checker plate to Colorbond and galvanised sheet, we deliver premium Australian-standard steel straight to your site.

Shop our steel sheet and plate range online and enjoy fast delivery anywhere in Australia, or purchase in-store at our locations in Brookvale, Revesby, Blacktown, Bathurst, or Orange.

Frequently Asked Questions

What’s the difference between steel sheet and steel plate?

Steel sheet is generally thinner than 6 mm and is used for lighter fabrication work like cladding, ducting, or toolboxes. Steel plates start at 6 mm thick and are used for structural or heavy-duty applications, such as base plates, chassis, or construction brackets.

Can I get steel sheet or plate cut to size?

Yes, Edcon Steel offers in-store cutting at all NSW locations, including Brookvale, Revesby, Blacktown, Bathurst, and Orange. You can also order online and request custom-cut sizes with fast delivery across Australia.

Do you deliver steel sheet and plate?

Absolutely. You can buy steel online from Edcon and have it delivered anywhere in Australia, whether you're in Sydney, regional NSW, or interstate. We also offer click-and-collect at all our NSW stores (Brookvale, Revesby, Blacktown, Bathurst, or Orange).

How do I choose between steel sheet and steel plate?

If your project needs a lightweight, flexible material for folding or covering, steel sheet is usually the best choice. If you’re building something structural, load-bearing, or heavy-duty, steel plate offers the strength and thickness required. Edcon Steel’s team can help you pick the right option based on your job.

Where can I find a steel supplier in Sydney or regional NSW?

Edcon Steel has five NSW locations: Brookvale, Revesby, Blacktown, Bathurst, or Orange. We also offer Australia-wide shipping when you buy steel online.