Cold-Formed vs Hot-Rolled Structural Steel: What’s the Difference?

If you’ve spent any time around construction sites, fabrication workshops, or steel suppliers like Edcon Steel, you’ve probably heard the terms cold-formed and hot-rolled steel. But what exactly do these terms mean? And why should you care?

While they both fall under the umbrella of structural steel, there are some key differences in how they’re made, their characteristics, and what applications they’re best suited for.

Whether you’re building a pergola at home, specifying steel for a new job, or trying to decide between materials for a shed frame, understanding these two types of steel can help you make the right choice.

Let’s break it down

Please note that all information provided is general in nature, and each reader is responsible for checking with the manufacturer or specifier before relying on any information provided.

Browse Edcon’s range of Structural Steel

What is hot-rolled steel?

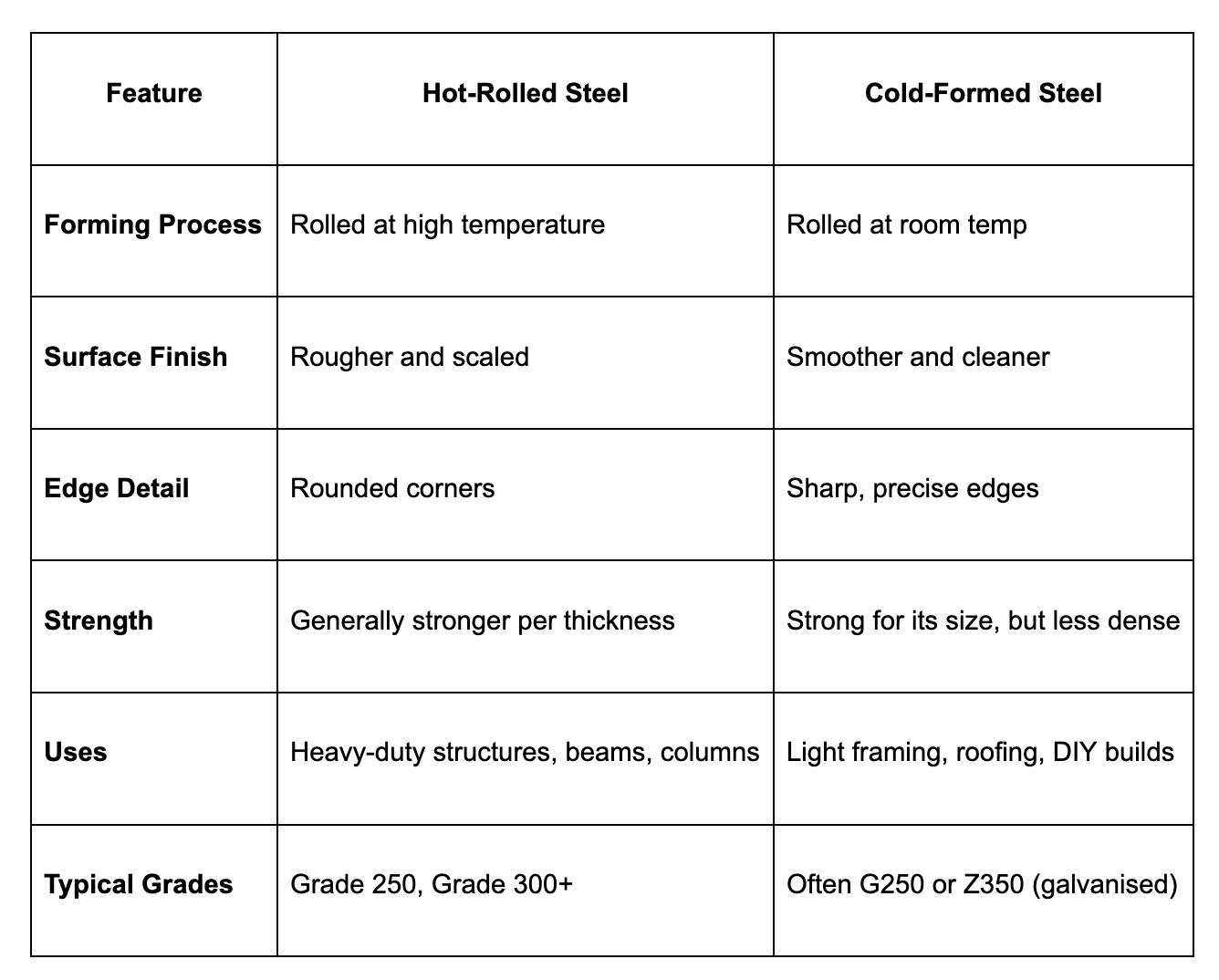

Hot-rolled steel is made by rolling steel slabs at very high temperatures, usually over 900°C. At these temperatures, the steel becomes malleable and can be formed into different shapes, such as beams, channels, angles, and plates.

Once shaped, the steel is cooled gradually. Because the steel is shaped while hot, it often has slightly rounded corners and minor surface scaling, which is a natural by-product of the process.

These products are commonly used in heavy-duty applications like residential and commercial framing, structural supports, lintels, bracing, and more.

What is Cold-Formed Steel?

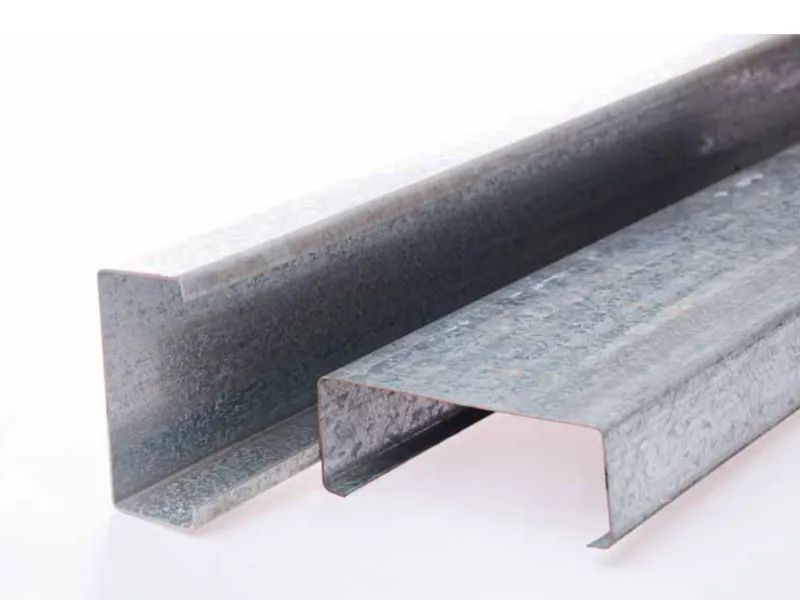

Cold-formed steel (also called cold-rolled or cold-pressed) is made at room temperature by pressing or rolling flat steel into shape. Because there’s no high heat involved, the steel maintains a tighter, more accurate finish and often has sharper edges and smoother surfaces.

Cold-forming is generally used for lighter-gauge materials and allows for thinner, more precise sections. Think of steel purlins, lightweight stud framing, or pressed channels used in garage and shed construction.

These are widely used in lightweight framing, DIY builds, or anywhere you need strength without excess weight.

Which One Should You Use?

Here’s where it really comes down to your project type, structural needs, and environmental conditions. At Edcon Steel, we can provide basic guidance, but for more specific expertise, you’ll have to talk to your builder or engineer. As a general guide:

Choose Hot-Rolled Steel if:

- You’re building a structural frame, house slab, or retaining wall

- The steel will bear heavy loads or span long distances

- You need weldable, durable steel

- You need thicker, stronger sections like beams, columns or heavy lintels

Choose Cold-Formed Steel if:

- You’re building lightweight frames, sheds or garages

- You’re installing roof battens or wall purlins

- You want ease of handling and fast installation

- You’re on a DIY budget or need precision cuts

What About Outdoor Use?

In Australia, where coastal and high-moisture environments are commonplace, corrosion resistance is often a deciding factor.

Cold-formed steel is often pre-galvanised or zinc-coated (aka pregal), making it a good fit for lighter outdoor structures like pergolas, carports and fencing. However, hot-dip galvanised (aka HDG) hot-rolled steel is superior for high-exposure applications because it offers full coating protection, even on welds and cut edges.

At Edcon Steel, we stock HDG structural sections, including beams, channels, and plate, which are ideal for long-term durability in weather-prone environments.

Working With Both

Both hot-rolled and cold-formed steel can be drilled, cut, and welded, but they behave slightly differently when used with different tools.

Hot-rolled steel is easier to weld and fabricate due to its lower carbon content and predictable density. In contrast, cold-formed steel is more brittle under stress and heat, and is generally not recommended for heavy welding jobs.

If you’re cutting either type to size, Edcon Steel can help with that, too. Each of our stores is equipped with cold saws, bandsaws, and fabrication gear to give you accurate, trade-ready steel cuts fast, saving you time on-site.

Buy steel and metal from Edcon Steel

At Edcon Steel, we pride ourselves on the expertise of our staff, our level of customer service and the depth of our local market knowledge. You can visit our stores to browse the range or pick up an online order.

Our staff are on hand to answer any questions you have about our full range of products and services, so feel free to contact us for your steel or metal solution today.

FAQs

What’s the difference between hot-rolled and cold-formed steel?

Hot-rolled steel is shaped at very high temperatures, making it ideal for strong, heavy-duty structures. Cold-formed steel is shaped at room temperature, resulting in smoother finishes and precise edges. It is often used in lighter, more accurate applications.

Which steel is better for heavy structural projects?

Hot-rolled steel is best for large structural frames, columns, beams, and retaining walls because of its strength and weldability.

Is cold-formed steel suitable for outdoor use?

Yes. Cold-formed steel is often pre-galvanised or zinc-coated, making it good for pergolas, carports, and fencing. However, hot-dip galvanised hot-rolled steel is superior for high-exposure, long-term outdoor applications.

Can both hot-rolled and cold-formed steel be welded?

Yes, but with differences. Hot-rolled steel is easier to weld and fabricate, while cold-formed steel is more brittle under heat and not recommended for heavy welding jobs.

How do I know which type of steel is right for my project?

It depends on your project type, load requirements, and environment. Use hot-rolled steel for heavy loads and structural strength, and cold-formed steel for lightweight framing, roofing, and precision cuts. When in doubt, consult your builder or engineer.