Bryan’s Model Steam Locomotive Project: Silver Steel & Gauge Plate in Action

When Bryan Homann talks about his model steam locomotive, it’s clear this isn’t just a hobby; it’s a lifetime of curiosity, patience and engineering instinct brought together in steel.

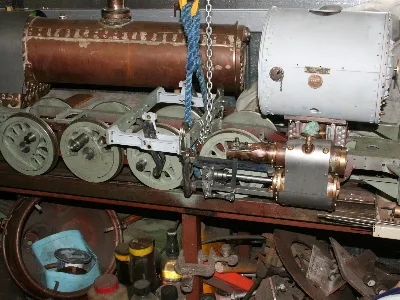

Now 80 years old and based in Carey Gully in the Adelaide Hills, Bryan is a retired mechanical engineer with decades of hands-on experience, a deep love of steam and railways, and a long-standing connection to the model engineering community. His prize winning Edcon Steel project, a meticulously crafted 1/8th scale model steam locomotive using silver steel and gauge plate, has been more than 20 years in the planning and over a decade in the making so far.

“I’ve been interested in model making since primary school,” Bryan says. “Like a lot of little boys I was interested in railways.”

But this early fascination never left him.

“My first job when I left school was as a trainee engineer at BHP in Whyalla,” he explains. “And they had just started a model engineering club, so I joined,”

This early interest evolved into a career in mechanical engineering, involvement with the heritage railways, leadership roles in engineering clubs, and eventually into the extraordinary project that caught the judges’ attention in this year’s Edcon Steel Project Competition.

The Inspiration Behind the Locomotive

As Bryan’s third steam locomotive build, the current project isn’t a generic model, it’s a scaled replica of a specific class of steam engines once used by BHP on its iron ore railway in Whyalla.

“There were four of them used by BHP at Whyalla,” Bryan explains. “I never actually saw them in service as they’d been cut up just before I went there for work, but I’d seen photographs and they always intrigued me.”

At the time they were introduced in 1920, these Mikado type locomotives were the largest and most powerful in Australia. Bryan eventually managed to source original drawings dating back nearly a century.

“I’ve been looking at building it for about 20 years before I got around to it,” he says. “And I’ve been working on it for about 10 years now.”

This isn’t a quick build or a kit assembly. Every component has required careful interpretation, redesign, and adjustment to work at a reduced scale, while still performing mechanically.

Browse Edcon’s range of metal

From Mechanical Engineer to Master Model Maker

Bryan’s professional background laid the groundwork for the skills required to take on a project of this scale. Trained as a mechanical engineer, he spent much of his working life solving problems, interpreting drawings, and thinking practically about how components fit and function together.

While he’s quick to point out that he’s not formally trade-trained in metal work and fabrication, his experience puts him well beyond beginner level.

“I’d say I’m reasonably well advanced as an amateur,” he explains. “But not in the same realm as someone who’s been formally trained as a tradesman.”

That blend of professional engineering knowledge and hands-on experimentation is exactly what model engineering demands, and Bryan has been immersed in it for decades. He’s a long-term member of the South Australian Society of Model and Experimental Engineers Inc, an organisation founded in 1927 and preparing for its centenary.

Over the years, Bryan has served as both President and Vice President of the society, while also continuing to build and refine his own projects in his home workshop.

Designing Without a Safety Net

Unlike modern technical drawings, the original locomotive plans offered limited guidance.

“These drawings were made at a time when everyone in the workshop just knew what they were doing,” Bryan explains. “They don’t show tolerances, or sometimes even what materials parts were made from.”

As a result, planning is never really finished.

“The planning stage is ongoing,” he says. “I probably spend more time lying in bed thinking about the next job than actually cutting metal.”

Scaling down full-size industrial machinery brings its own challenges. Not everything can simply be reduced proportionally.

“You can’t just shrink everything down literally and expect it to work,” Bryan explains. “Sometimes you make a part, realise it’s not quite right, and the next pieces have to be adjusted to suit.”

It’s a process that demands patience and a willingness to remake parts when needed.

Materials Sourced from Edcon Steel

For Bryan, reliability matters, and as an interstate customer of more than five years, he finds the Edcon website great for making technical purchasing easier.

“Once you’ve got an account, it’s very easy to check prices and sizes,” he says. “That was really helpful with the gauge plate, especially being able to compare metric and imperial.”

For customers outside NSW, Bryan’s experience highlights the values of Edcon’s clear product information, dependable delivery, and responsive customer service, regardless of location.

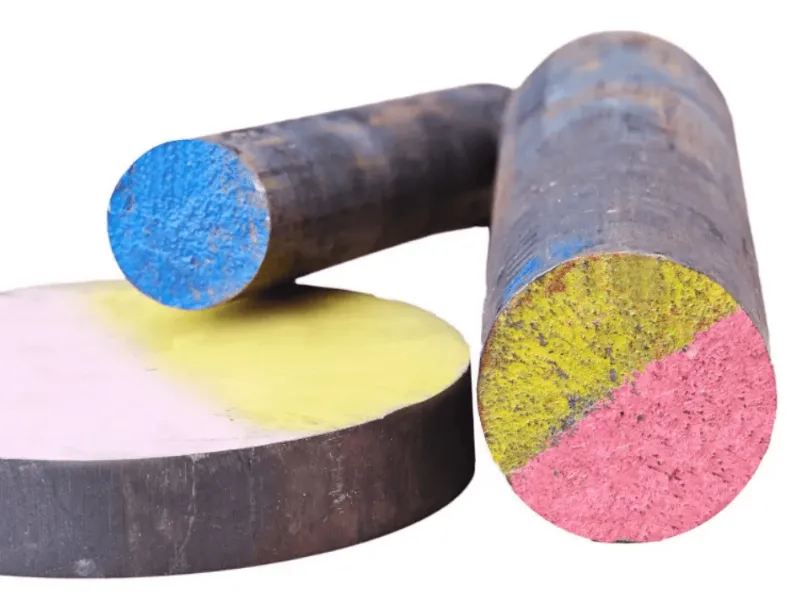

For this project, Bryan sourced many of his materials directly from Edcon Steel, including silver steel and gauge plate.

“Silver steel is great because you can heat treat it at home,” Bryan explains. “You don’t need specialised equipment to harden it.”

The gauge plate was chosen for different reasons.

“It comes already ground, nice and square,” he says. “That made it much easier to finish-grind it to the exact size I wanted.”

While Bryan didn’t require custom cutting for this particular build, he values the flexibility Edcon offers, particularly the ability to compare metric and imperial sizes online and plan purchases to minimise waste.

“I could work out the best sizes to order and even cut some pieces in half to reduce wastage,” he says.

Built entirely by hand

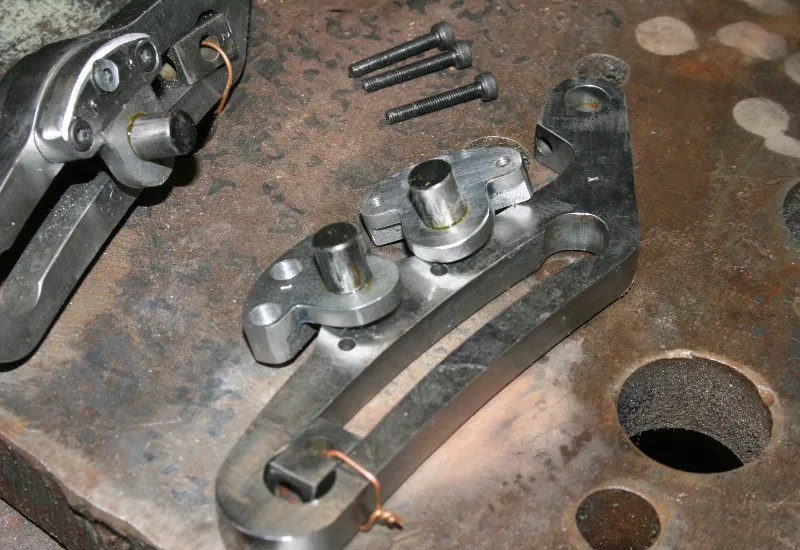

Every major component of the locomotive, aside from a small number of castings, has been made by Bryan himself.

“I’ve done it all myself,” he says. “With the exception of the driving wheel castings, and some laser cut sheet metal everything else I’ve made.”

His home workshop is extensive, equipped with lathes, milling machines, a shaping machine, welding equipment, a surface grinders, and even a blacksmithing and foundry setup.

Bryan also credits his wife of 55 years, Mary, whose long-standing involvement in the model engineering community and constant encouragement have been an important part of his ability to take on projects of this scale.

“I’ve been very fortunate in having my wife by my side for this,” he says. “She doesn’t just encourage me, but gets involved, but not in the shed!”

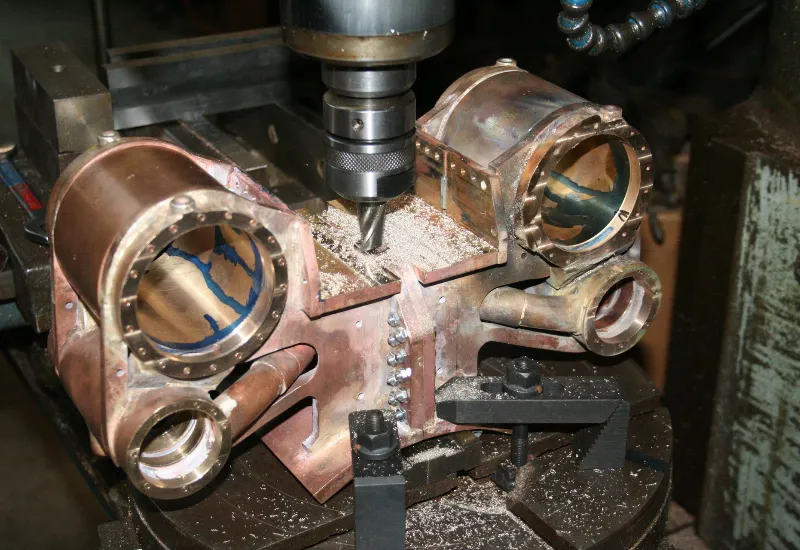

One of the standout components of the model steam locomotive is the cylinder block, which Bryan considers the part he’s most proud of.

“I decided it was better to silver solder it together out of several components rather than cast it in one piece,” he explains. “That meant setting it up and machining it after everything was assembled. It was a lot of work.”

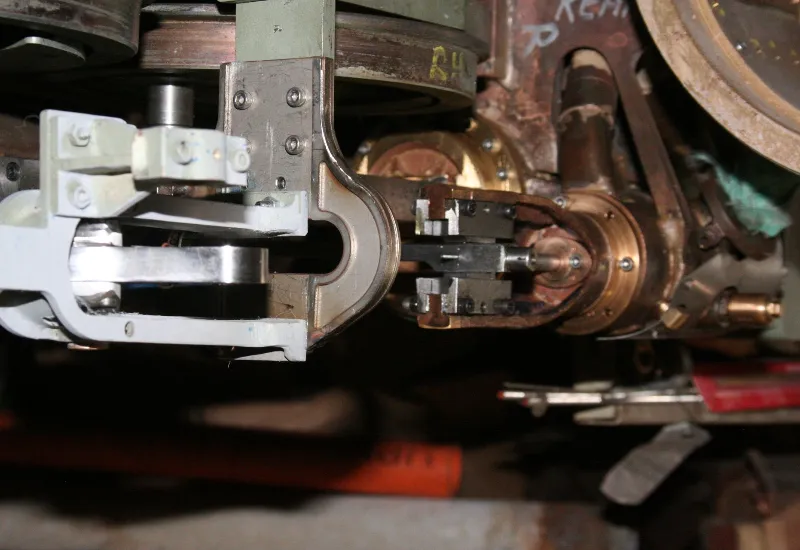

Although many of the major components are complete, the locomotive isn’t finished yet.

“The big heavy parts are done,” Bryan explains. “But there’s still an awful lot of bits and pieces.”

Like many large projects, the final stretch is the longest.

With Edcon Steel materials supporting the build from the ground up, and decades of experience guiding every decision, this project stands as a testament to patience, precision and the joy of making something that lasts.

Inspired by Bryan’s project?

Explore Edcon Steel’s range of silver steel, gauge plate and precision metals, with custom-cut options and Australia-wide delivery. Browse our stores in Brookvale, Revesby, Blacktown, Bathurst, and Orange, or check out the full range online. With Australia-wide delivery, getting started is easy.

FAQs

Which Edcon Steel stores can I visit in NSW?

Edcon Steel has physical locations in Brookvale, Revesby, Blacktown, Bathurst, and Orange, making it easy to access materials across metropolitan and regional NSW.

Do you deliver steel and metal Australia-wide?

Yes. While many customers are based in NSW, Edcon Steel provides Australia-wide delivery for custom-cut and standard metal orders. Our Edcon Steel trucks deliver daily to sites across Sydney and Central Western NSW (including Bathurst and Orange). For areas outside our truck network, we partner with reliable national freight providers to get your order to you safely and efficiently.

Can Edcon Steel custom-cut materials before pickup or delivery?

Absolutely. all Edcon Steel stores in Brookvale, Revesby, Blacktown, Bathurst, or Orange, as well as our online store, offer precision custom cutting services. We cut and prepare orders for in-store pickup or delivery nationwide.

Can I order online then pick up my order in-store?

Yes, you can opt for click-and-collect pickup at any of our NSW stores (Brookvale, Revesby, Blacktown, Bathurst, or Orange). We’ll prepare your order, and you can pick it up at a time that suits you. Our friendly staff will even help load your vehicle if needed.

How do I get a quote or check pricing?

You can view live prices or request a quote online 24/7. Or contact any of our NSW steel stores for fast, friendly help with pricing, including cutting and delivery options. For an accurate price, simply select your desired product online or contact our team, and we’ll provide a prompt quote.

Is Edcon Steel suitable for both trades and home DIYers?

Definitely. Edcon Steel supports builders, fabricators and tradespeople, as well as home DIY enthusiasts looking for quality materials, expert service and flexible ordering options.

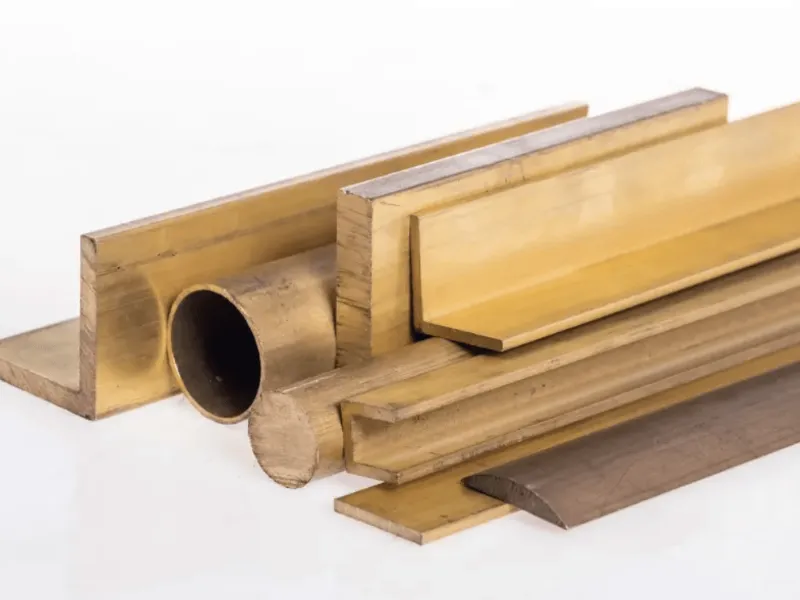

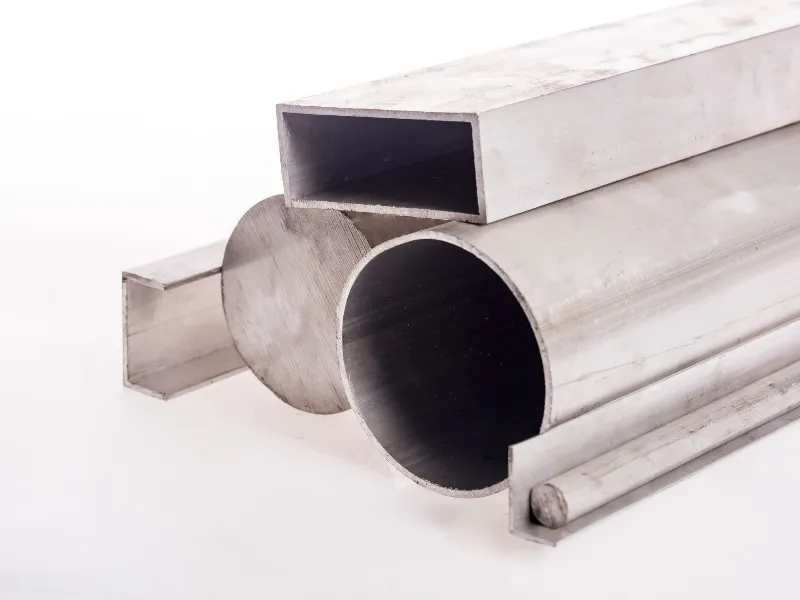

Do you stock aluminium and brass for small DIY projects?

Yes. Edcon Steel stocks aluminium, brass and many other metals suitable for everything from small DIY projects to large-scale trade work, available online and in-store across NSW (Brookvale, Revesby, Blacktown, Bathurst, and Orange).

Can I get a special grade or size that’s not listed on your website?

Generally, yes. If you require a specific steel or metal grade or a size that you don’t see listed online, we can usually source or special-order it for you. Edcon Steel has an extensive supplier network, so just let us know what you’re after. Our team is happy to help with custom orders or hard-to-find items to ensure you get the right steel for your project.