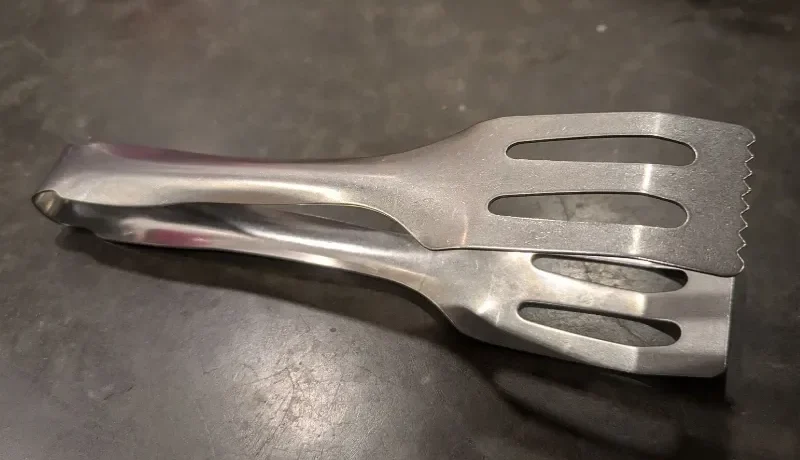

2025 Project Competition Runner-Up: Daniel Seidels kitchen tong press tooling

Congratulations to Daniel Seidel, a 2024 Project Competition Runner-Up, for his kitchen tong press tooling for an Australian kitchenware company.

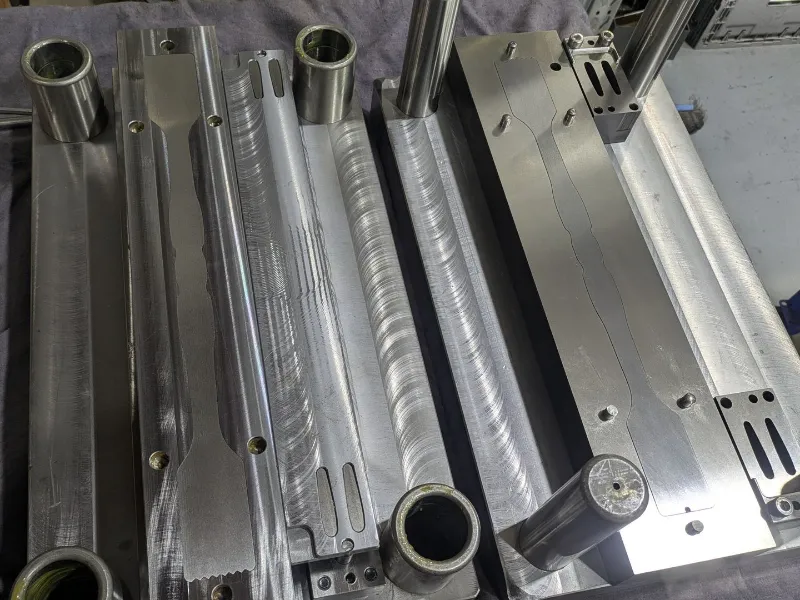

Using O1 tool steel ground stock and 4140 round bar, Daniel created a stamping and cutting punch-and-die progressive tool for his client.

A toolmaker by trade, Daniel is based on the South Coast of NSW and has travelled and contracted with various engineering clients, including Victa Lawnmowers, where he worked on product design and development.

Passionate about trade and Australian manufacturing in general, Daniel recently established his own engineering workshop, LKT Design and Tool,, which specialises in the design and manufacture of custom tooling for various clients.

The inspiration

“I’m a hands-on toolmaker who works the whole process. So I assist with the product design, I have a thorough understanding of what the tool will be capable of, and then I make the whole thing in my workshop,” Daniel explains.

“As a one-person toolmaking shop, I’m committed to revitalising the Australian toolmaking industry. And my hope is to train more young people in the trade.”

The process

The process began with an outline of the product requirement. The client wanted a press tool for the manufacture of high-end kitchen tongs. This allows the client to manufacture their own kitchen tongs using the tooling that Daniel created.

“The client and I collaborated in the production of the design using CAD”, Daniel explains.

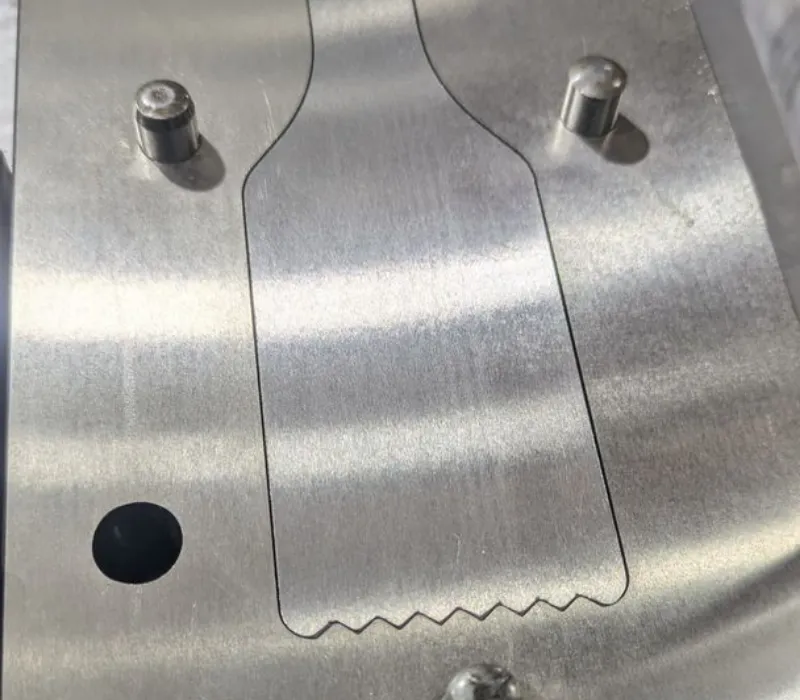

“Once we got to a 3D CAD model, I started to produce the tool. The tool that I have designed is what is known as a progressive stamping and cutting punch-and-die tool made from O1 tool steel, specifically for manufacturing kitchen tongs.”

A progressive tool has multiple stamping stations to carry out simultaneous operations on sheet metal. By combining all the necessary tools into one die set, progressive die stamping is an efficient solution for high-volume production runs.

“The first stage of the progressive tool cuts out the shape, then it punches out the holes in the centre, then it is formed to a shape, then bent into the u-shape.”

As I’m designing the tool, I need to understand what type of material will be pressed. Is it stainless steel, titanium? I need to get the material hardened so that it doesn’t go blunt and is able to cut through and blank out parts.

Long-time customer

One of the most challenging aspects of tool manufacturing is sourcing high-end engineering steels.

“Edcon provide the high-end engineering steel I need, like O1 toolsteel ground stock and 4140 round bar. This is the material I need for cutting blades, as they can be hardened and allow me to grind it to a sharp knife to be able to punch out blanks,” Daniel says.

“I’ve been going to Edcon Steel for quite a while, siince my sub-contracting days. Their turnaround time is within a few days, so they’ll have the material cut and ready to pick up. They also have tool steel on the shelf, which I can pick up as needed, which is great.”

Buy online from Edcon Steel

At Edcon Steel, we pride ourselves on the expertise of our staff, our level of customer service and the depth of our local market knowledge.

You can visit our stores to browse the range or pick up an online order. Our staff are on hand to answer any questions you have about our full range of products and services, so feel free to contact us for your steel or metal solution today.